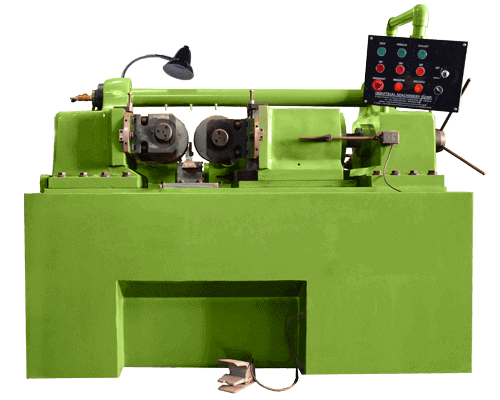

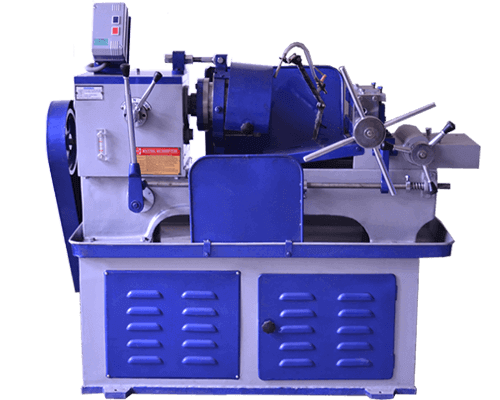

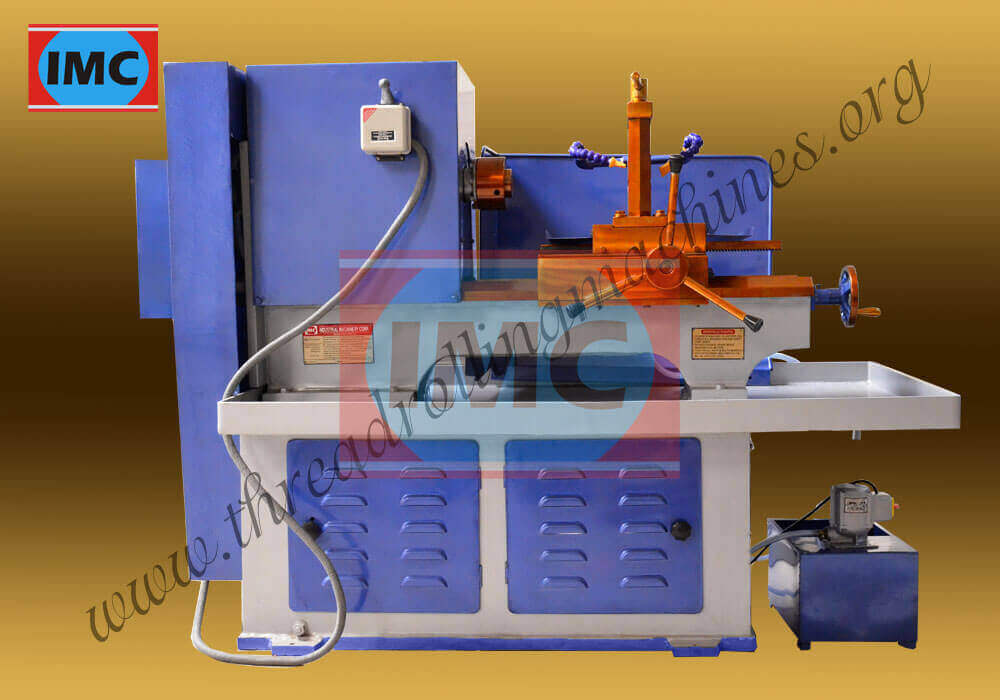

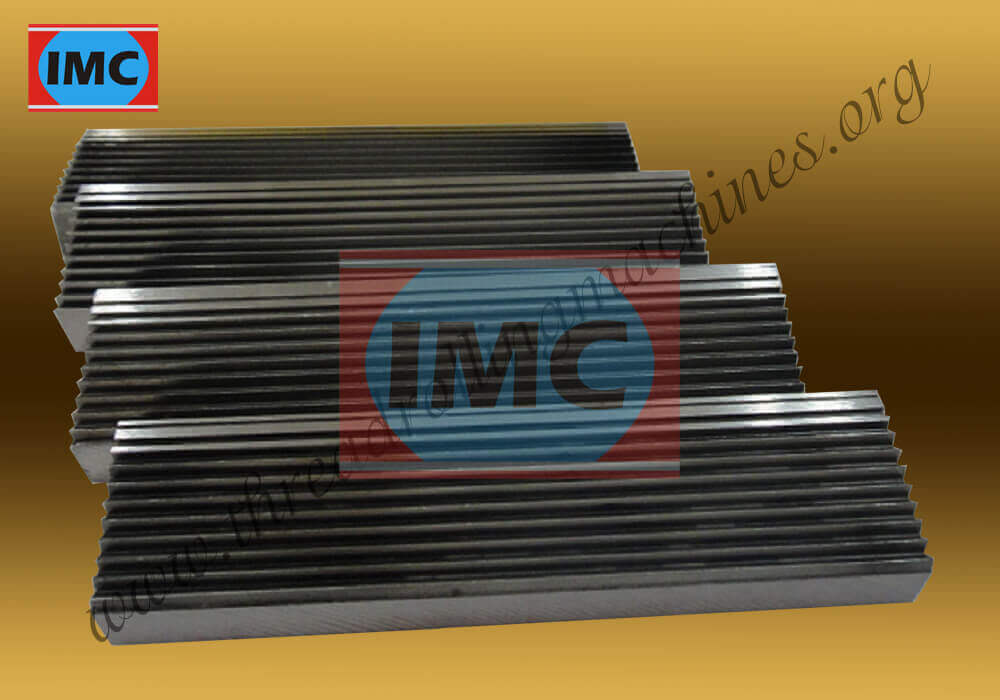

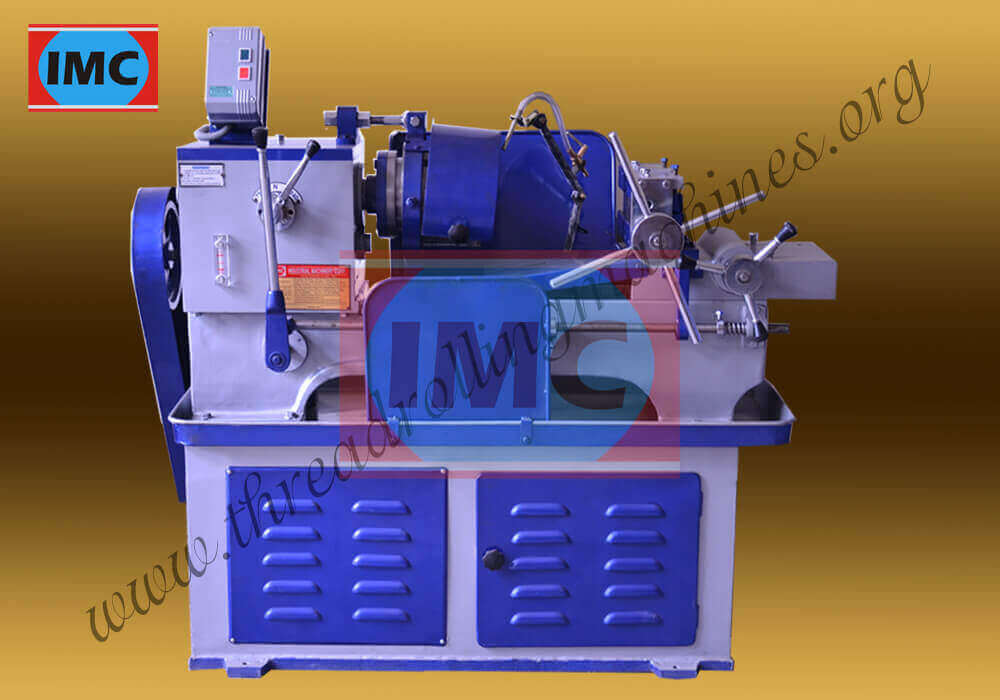

HYDRAULIC THREAD ROLLING MACHINE 2 ROLL

Industrial Machinery Corporation are engaged in manufacturer of Hydraulic Thread Rolling Machine 2 Roll use for producing screws, bolts and tools. It is a cold-forming operation only for external screws threads in a blank. The blank is pressed by thread rolling dies which are attached to the machine. The threads were formed by the pressing progress.

We have 3 Different Models for Thread Rolling Machines:-

1) Hydraulic Thread Rolling Machine 2 Roll Type

2) Hydraulic Thread Rolling Machine

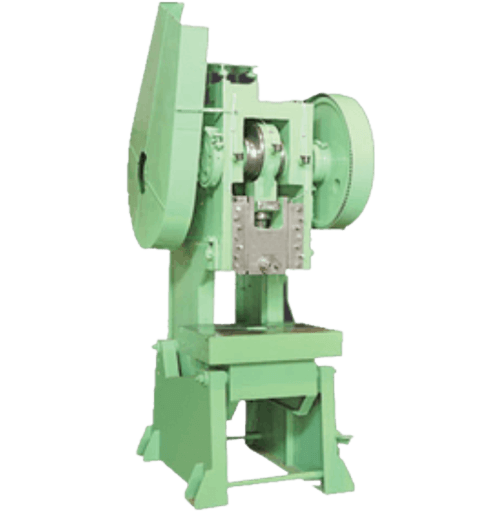

C TYPE POWER PRESS MACHINE

Industrial Machinery Corporation is leading Manufacturer and Supplier of wide range of Power press machine. Power press machine are made of high grade material. Power press machine comes in two models C type power press machine and H type power press machine. The Power Press machine can be customize as per the requirement of the client. Power press is available in very reasonable prices. The clutch of rolling key type which gives continuous strokes and produce mass production.

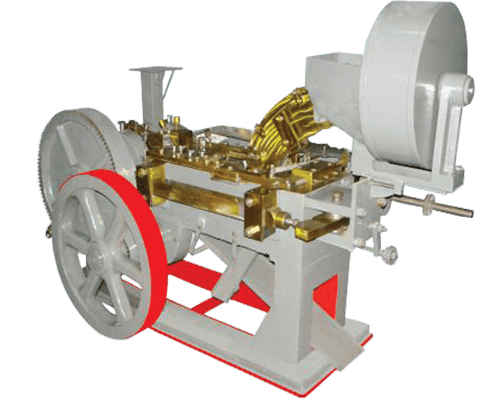

AUTOMATIC BOLT HEAD TRIMMING AND SHANK REDUCING MACHINE

We have been making these machines with full honesty and truthfulness and supplying them to our worldwide clients. It is due to our best quality service that we are now acknowledged as one of the best suppliers of many industrial machines including cold head making machine. We have gained special expertise in making our cold head making machine which has been admired by all who used our cold head making machines. The best part while we make our cold head making machine, a bolt head machine.

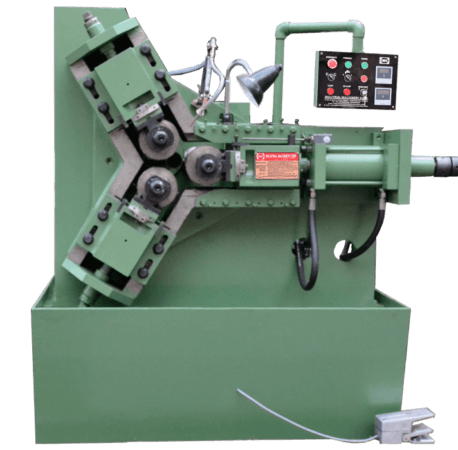

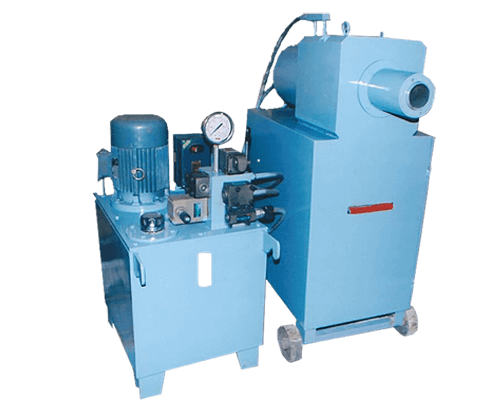

HYDRAULIC THREAD ROLLING MACHINE 3 ROLL

We are Dealing in Scaffolding Machinery Unit Such as:-

2) Scaffolding Thread Cutting Machine.

3) Internal Threading Machine.

4) C Type Power Press Machine.

5) Pipe Cutting Machine.

6) Multi Drilling Machine.

7) Cup Lock Welding Machine.

8) Cups and Lock Pins Tagging Machine.

9) Horizontal Ledger Welding Machine.

10) Outer Prop Welding Machine.

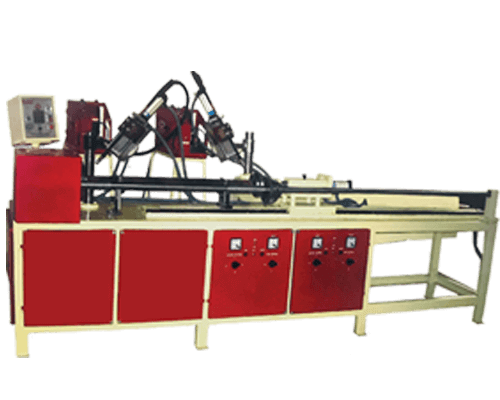

HORIZONTAL LEDGER WELDING MACHINE

We are Dealing in Scaffolding Machinery Unit Such as:-

1)Hydraulic Thread Rolling Machine

2) Scaffolding Thread Cutting Machine

3) Internal Threading Machine

4) C Type Power Press Machine

5) Pipe Cutting Machine

6) Multi Drilling Machine

7) Cup Lock Welding Machine

8) Cups and Lock Pins Tagging Machine

9) Horizontal Ledger Welding Machine

10) Outer Prop Welding Machine

HYDRAULIC TMT BAR FORGING MACHINE

REBAR COUPLER DRILLING AND CUTTING MACHINE

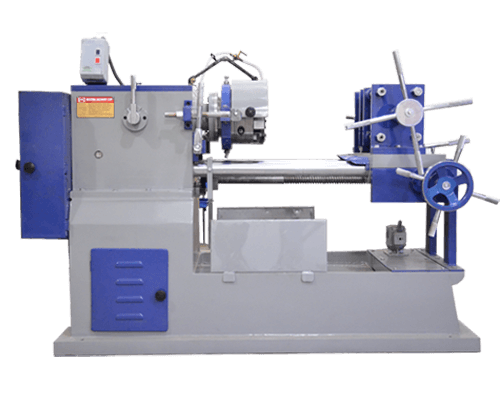

PILLAR TYPE THREADING MACHINE

We have Largest range of Threading Machines from 1/4" upto 8" diameter and We have two Types of models Available in this Range

1) Bed Type Threading Machines

2) Pillar Type Threading Machines

Pillar Type Threading Machine Model is also use to thread the MS Pipe, Scaffolding Pipes, Conduit Pipe, PVC Pipes, Round Bars, Rod, & Bolt and it covers almost range start from 3/8" upto 8" diameters.

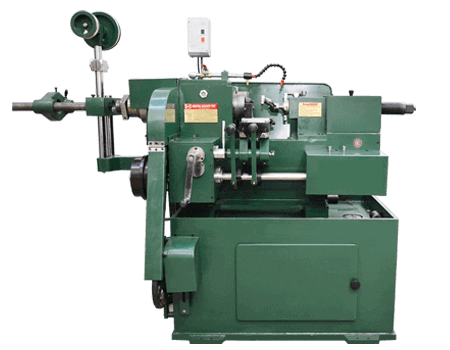

BED TYPE THREADING MACHINE

We have Largest range of Threading Machines from 1/4" upto 8" diameter and We have two Types of models Available in this Range

1) Bed Type Threading Machines

2) Pillar Type Threading Machines

Bed Type Threading Machine Model is mostly using to thread the Rod, Round Bars, Bolt, PVC Pipe, Scaffolding Pipe, Conduit Pipe & TMT Rebar and mostly covering the range start from 1/4" upto 2.1/2" Diameter.

Algeria

Algeria

Australia

Australia

Bangladesh

Bangladesh

Belgium

Belgium

Bhutan

Bhutan

Canada

Canada

Colombia

Colombia

Cyprus

Cyprus

Egypt

Egypt

France

France

Germany

Germany

Ghana

Ghana

Greece

Greece

Guatemala

Guatemala

India

India

Israel

Israel

Italy

Italy

Jordan

Jordan

Kuwait

Kuwait

Lebanon

Lebanon

Malaysia

Malaysia

Maldives

Maldives

Mexico

Mexico

Myanmar

Myanmar

Nepal

Nepal

Pakistan

Pakistan

Peru

Peru

Philippines

Philippines

Qatar

Qatar

Russia

Russia

Saudi Arabia

Saudi Arabia

Serbia

Serbia

Singapore

Singapore

South Africa

South Africa

Sri Lanka

Sri Lanka

Thailand

Thailand

Tunisia

Tunisia

Turkey

Turkey

Ukraine

Ukraine

United Arab Emirates

United Arab Emirates

United States

United States

Vietnam

Vietnam