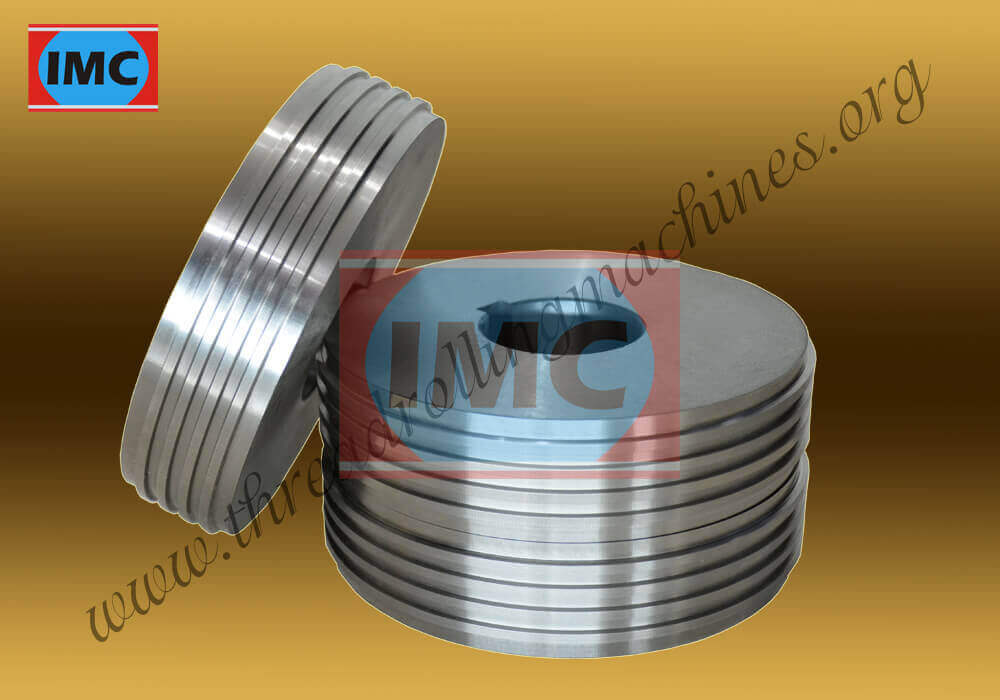

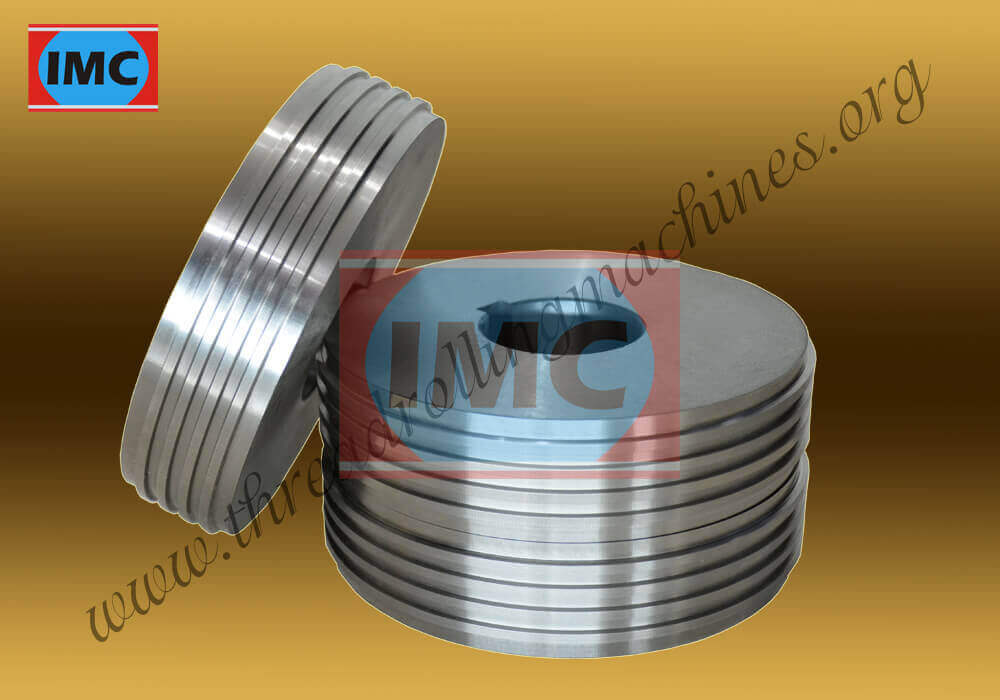

Circular Thread Rolling Dies

Industrial Machinery Corporation has been a renowned designer and manufacturers of industrial machinery since its formation in 2011. Since then only, we have been manufacturing a wide range of industrial machines and one of our very poplar machines is Circular Thread Rolling Dies. Industrial Machinery Corporation build not only Circular Thread Rolling Dies but all the varieties if thread rolling dies which are ready to provide accurate and précised thread rolling in fasteners, auto-parts and various other components. These Circular Thread Rolling Dies are generally made from cold work tools steel [D2 or similar] and also in high speed steel [M2]. We have proficiency in making three variants of Circular Thread Rolling Dies and they are:

- In feed

- Thru feed

- In feed type

Available Options

Specifications

In-Feed Thread Rolling Dies: in this die, the machine’s spindles are set to zero degrees and the part does not feed through the dies. The length of thread rolled from this Circular Thread Rolling Dies is limited to width of dies. These Circular Thread Rolling Dies are always helical. \nThru-Feed Circular Rolls: in this type of Circular Thread Rolling Die, the spindle is normally set to any angel other than zero. The work-piece feeds through dies. The length of threads produced from this type of die is unlimited. Angle for entry and exit of the feed can also be provided in this type of Circular Thread Rolling Dies. Following are the features of Circular Thread Rolling Dies that we manufacture here at our Ludhiana based manufacturing unit.

- Accuracy of the thread profile is excellent

- Tensile strength is greatly increased

- Higher quality surface finish

- Superior wear resistance

- Greater resistance to fatigue

- Increased resistance to corrosion

- Production far more efficient in terms of time and cleanliness

- Simple operation in terms of repetitious

Following is the information that you must have to share with us before opting to buy Circular Thread Rolling Dies:

- Roll’s outer diameter, bore, face width and key way size

- Type of dies- in-feed (plunge-feed) or thru-feed

- Threading-diameter and thread pitch along thread standard of fastener to be rolled

- Quality -regular for general thread rolling and premium for stainless steel and hard material rolling.

- Angle of entry & exit- for thru feed rolls

- Any special operation- radiuses run out grinding, chamfer angles other than standard 30 deg, etc.

- Do mention the component hardness while ordering for rolls for AHT operation.