Mig Welding Machine

Mig Welding Machine which means Metal Inert Gas Welding and it is also known as (GMAW) Gas Metal Arc Welding which is broadly used in shipbuilding, auto industries as well as in heavy and light fabric ...

VIEW MORE

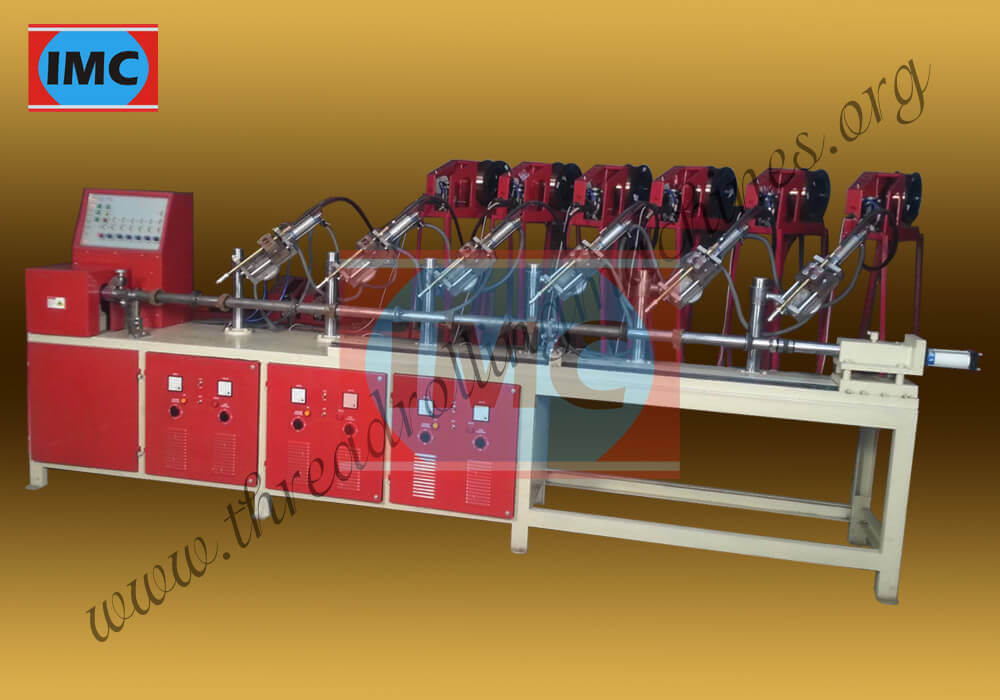

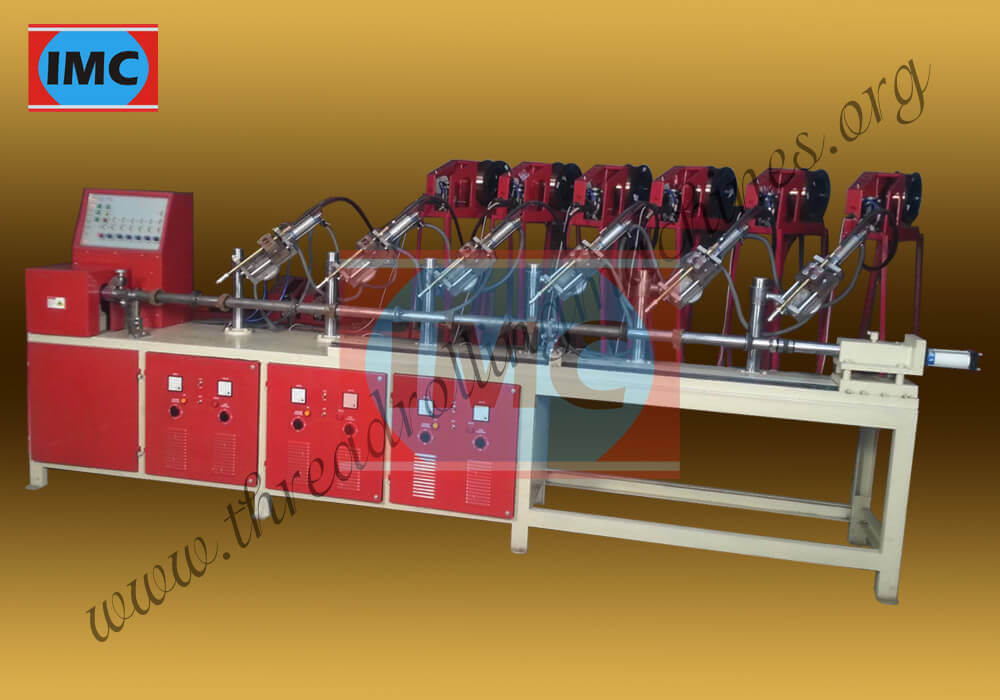

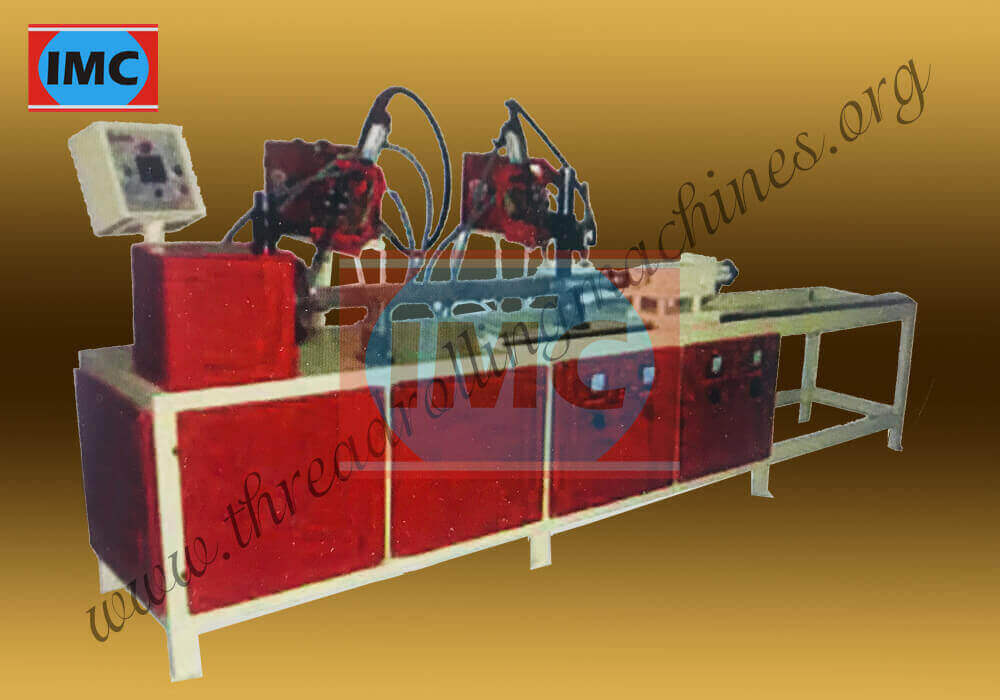

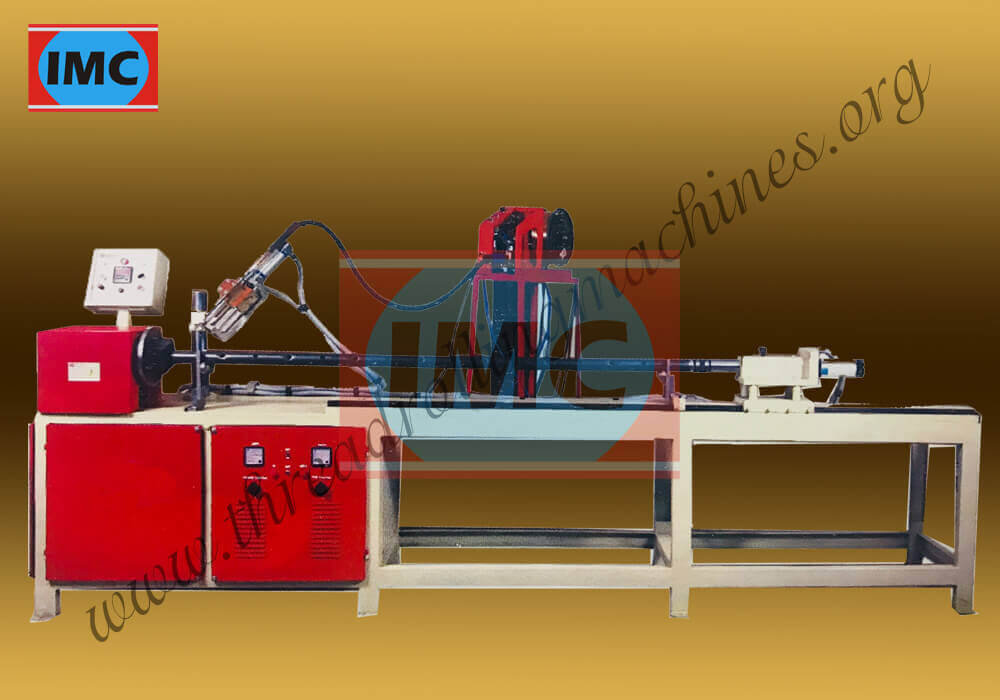

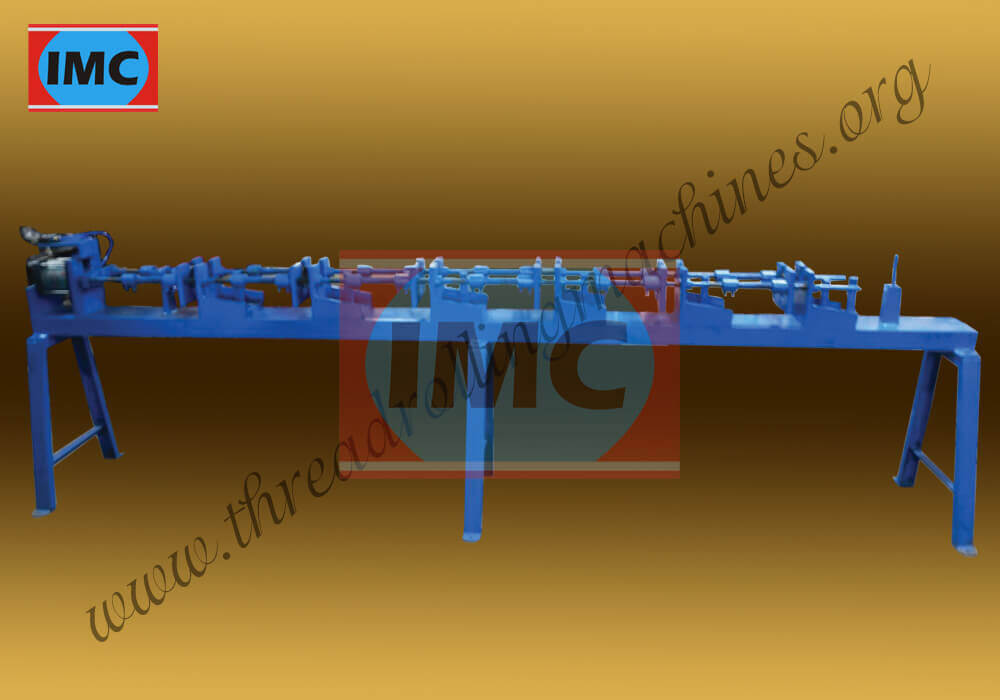

The main feature of this Automatic Cuplock Welding System is mostly used to weld six cups at the time with the pipe on a tagging fixture. Cuplocks is one of the main components of this machine which are used to make a structure with the combination of Base jacks and ledger posts. It offers the more accuracy, best performance and high production of products. These Cuplocks with the combination of other components are recycled in Outer Prop Welding machines, Base Jack Welding Machines, Inner Prop welding Machines, Cuplock Welding Machines as well as Ringlock Welding Machines. It is easy to operate and well-balanced to maintain. The main features of this machine are below:

The one of the main reason is behind that we used the advanced programmable technology, 100% standardized raw material, updated and modern work methods which gives great production efficiency and also reduces the labor intensity. This machine has main quality is that it saves the consumption of CO2 Gas & weld with an appropriate welding thickness on every single processor operation.

The Industrial Machinery Corporation provides latest complete solutions for Automatic Scaffolding Machines. The main Technical Specifications of Cuplock Welding Machine are below:

| Input voltage | 3- phase 380-415 V 300A |

| Control system input voltage | 3- phase 380-415 V |

| Control system | 1kw |

| Motor power | .86 kw |

| Speed | 6-25 s/round |

| Poling | 1-3 m (2-6 pics) |

| Welding torch distance | 500 mm |

| Motion way | Pneumatic |

| Welding angle | 0-600 Degree |

| Maximum work piece number | 6 pics |

| Dimension | 3900X800X1700 mm |

| Machine area | 4.5X3.5m |

| Weight | 1.5T |

The main thing is that the input voltage of this machine is 3 phase 380-415 V 300A, high speed is 6-25s/round and control system is 1kw. It covers a total 4.5X3.5m area for maximum production as well as their dimension is 3900X800X1700mm. Moreover, we used hundred percent certified and quality-approved raw materials for the manufacturing of Cuplock Welding Machines, which gives us a high standard of our products.

Mig Welding Machine which means Metal Inert Gas Welding and it is also known as (GMAW) Gas Metal Arc Welding which is broadly used in shipbuilding, auto industries as well as in heavy and light fabric ...

VIEW MORE

Industrial Machinery Corporation is an ISO certified organization, engaged in manufacturing and exporting of Threading Machine, Thread Rolling Machine, Scaffolding Welding Machine, Rebar Coupler Machi ...

VIEW MORE

Today, the importance of Inner Prop Welding Machines is constantly increasing in auto industries, light and heavy fabrication work. We used best quality raw material, standardized advanced technology ...

VIEW MORE

Industrial Machinery Corporation provides our clients with a comprehensive range of Base Jack Welding Machine, which is dimensionally accurate and wears & tear resistant. These are corrosion-resistant ...

VIEW MORE

Industrial Machinery Corporation is the well known standardized company which engaged in exporting as well as in the manufacturing of Scaffolding machines like Horizontal Ledger Welding System, Cup Lo ...

VIEW MORE

Industrial Machinery Corporation has been in the business of manufacturing welding machines for more than a decade now. By being in this business for so long, we have acquired a vast experience and ex ...

VIEW MORE

Industrial Machinery Corporation (IMC) presents the Scaffolding Pipe Punching Machine, a state-of-the-art solution designed to streamline the hole-making process in scaffolding pipes. Meticulously cra ...

VIEW MORE

Industrial Machinery Corporation (IMC) proudly introduces the Scaffolding Prop Nut Cup Handle Welding Machine, a cutting-edge solution designed to revolutionize the welding process for prop nut cup h ...

VIEW MORE

Revolutionize your scaffolding production with Industrial Machinery Corporation's (IMC) Automatic Scaffolding Cup Sleeve Nut Handle & G Pin Making Machine. Designed for efficiency and precision, this ...

VIEW MORE

Industrial Machinery Corporation (IMC) introduces the Scaffolding Prop Welding Machine - Double-Sided, a state-of-the-art solution designed to streamline and enhance the welding process for scaffoldin ...

VIEW MORE