Mig Welding Machine

Mig Welding Machine which means Metal Inert Gas Welding and it is also known as (GMAW) Gas Metal Arc Welding which is broadly used in shipbuilding, auto industries as well as in heavy and light fabric ...

VIEW MORE

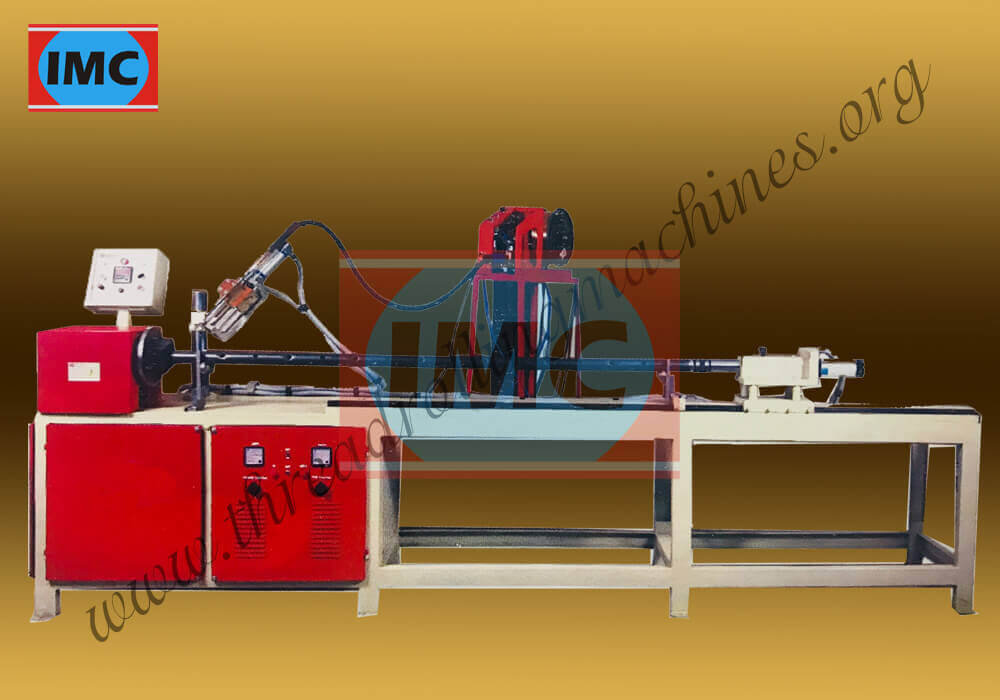

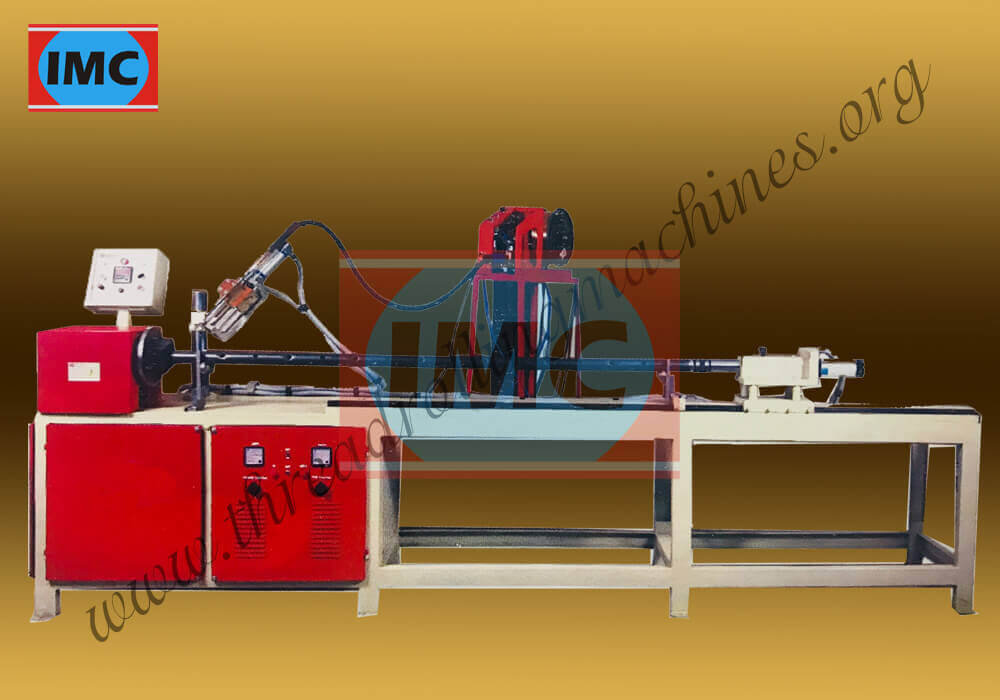

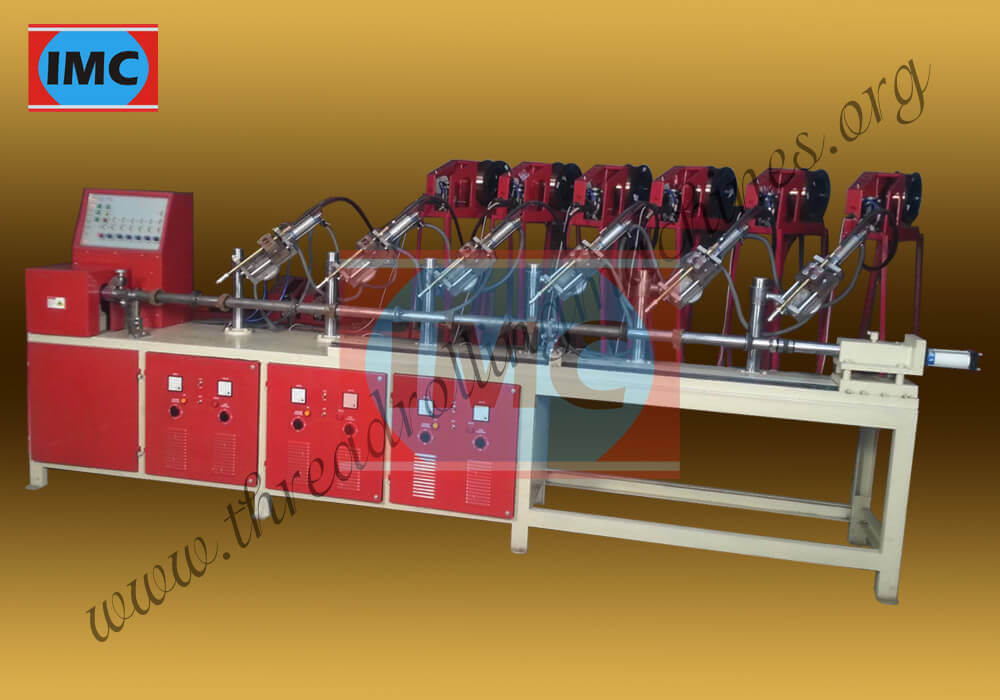

Today, the importance of Inner Prop Welding Machines is constantly increasing in auto industries, light and heavy fabrication work. We used best quality raw material, standardized advanced technology in the components of the Inner Prop Welding Machine that gives high efficient accuracy and more production within the time limit. Base plate is welded with pipe by using Inner Prop Welding machine without making any joint amongst them.

VIEW SPECIFICATIONSBasically, for making a new structure of the product, we used Inner Prop Welding Machine Equipment with the alternative of the Outer prop welding machine. All the modules of these machines are extremely useful which are used with the combination of including other equipment such as Cup lock welding machine, Ringlock welding machine, Inner prop welding machine, Outer prop welding machine and Base jack welding machine.

Therefore, the overall method or process is depended on circular welding on both base plates with pipe and pipe with the threaded sleeve from both positions, for instance: from top side or inside of the sleeve for fastest production as well as for uniform welding. Moreover, this method helps to machinist be safe from the sweltering skin of continuous welding process.

| Electric Supply | Single Phase 220 Volt HZ 50/60 |

| Speed | 2 to 10 RPM |

| Motor Drive | AC Inverter Type |

| Motor | Type AC 220-Volts-3-Phase |

| Torch Clamping | PNEUMATIC |

| Length Adjustment | 150 to 2400 mm |

| Dimension | L x W x H 11.3×2.5×5.3 (Foot) |

Mig Welding Machine which means Metal Inert Gas Welding and it is also known as (GMAW) Gas Metal Arc Welding which is broadly used in shipbuilding, auto industries as well as in heavy and light fabric ...

VIEW MORE

Industrial Machinery Corporation is an ISO certified organization, engaged in manufacturing and exporting of Threading Machine, Thread Rolling Machine, Scaffolding Welding Machine, Rebar Coupler Machi ...

VIEW MORE

Industrial Machinery Corporation provides our clients with a comprehensive range of Base Jack Welding Machine, which is dimensionally accurate and wears & tear resistant. These are corrosion-resistant ...

VIEW MORE

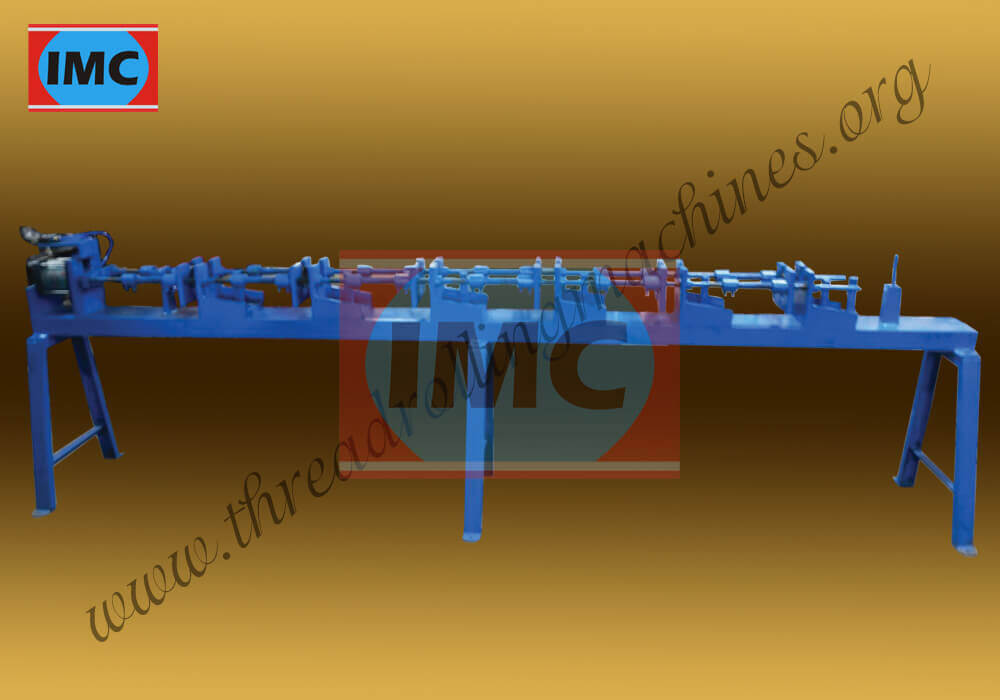

Industrial Machinery Corporation is the well known standardized company which engaged in exporting as well as in the manufacturing of Scaffolding machines like Horizontal Ledger Welding System, Cup Lo ...

VIEW MORE

Industrial Machinery Corporation has been in the business of manufacturing welding machines for more than a decade now. By being in this business for so long, we have acquired a vast experience and ex ...

VIEW MORE

The main feature of this Automatic Cuplock Welding System is mostly used to weld six cups at the time with the pipe on a tagging fixture. Cuplocks is one of the main components of this machine which a ...

VIEW MORE

Industrial Machinery Corporation (IMC) presents the Scaffolding Pipe Punching Machine, a state-of-the-art solution designed to streamline the hole-making process in scaffolding pipes. Meticulously cra ...

VIEW MORE

Industrial Machinery Corporation (IMC) proudly introduces the Scaffolding Prop Nut Cup Handle Welding Machine, a cutting-edge solution designed to revolutionize the welding process for prop nut cup h ...

VIEW MORE

Revolutionize your scaffolding production with Industrial Machinery Corporation's (IMC) Automatic Scaffolding Cup Sleeve Nut Handle & G Pin Making Machine. Designed for efficiency and precision, this ...

VIEW MORE

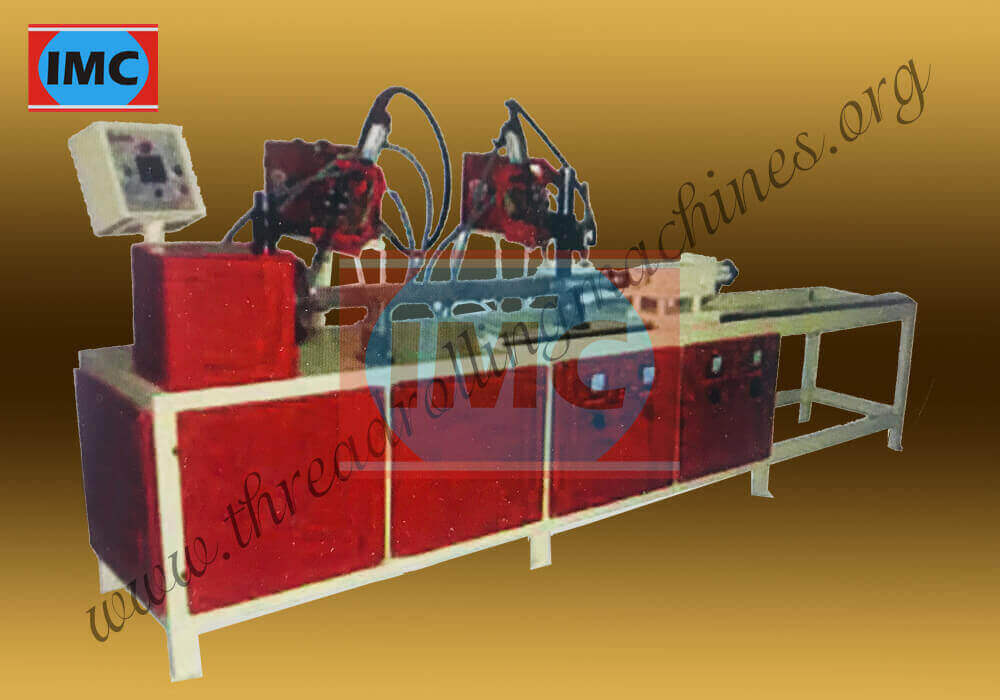

Industrial Machinery Corporation (IMC) introduces the Scaffolding Prop Welding Machine - Double-Sided, a state-of-the-art solution designed to streamline and enhance the welding process for scaffoldin ...

VIEW MORE