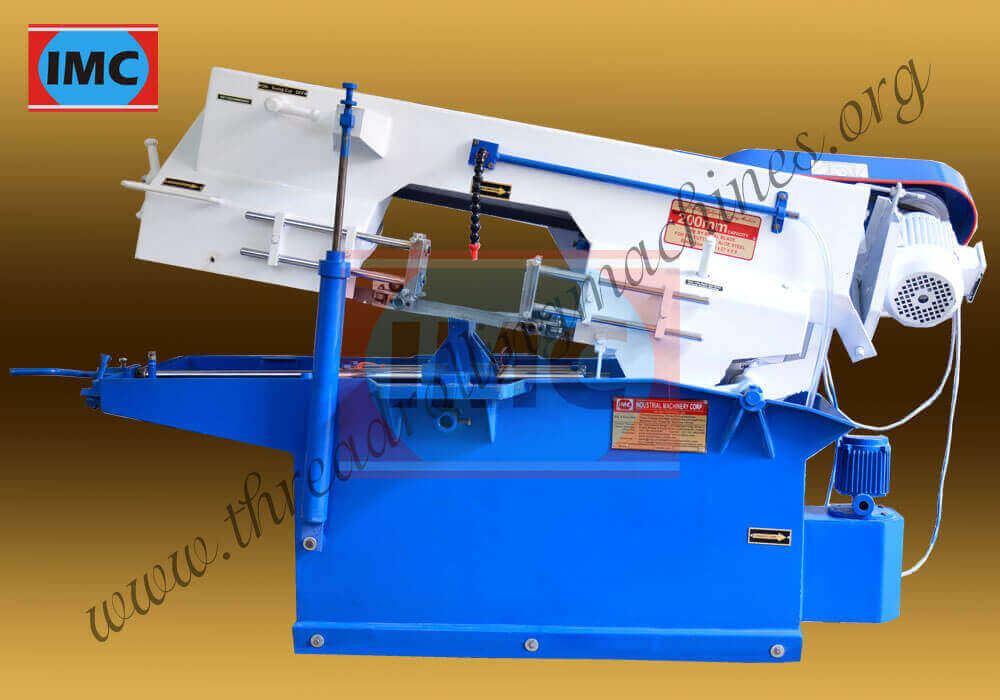

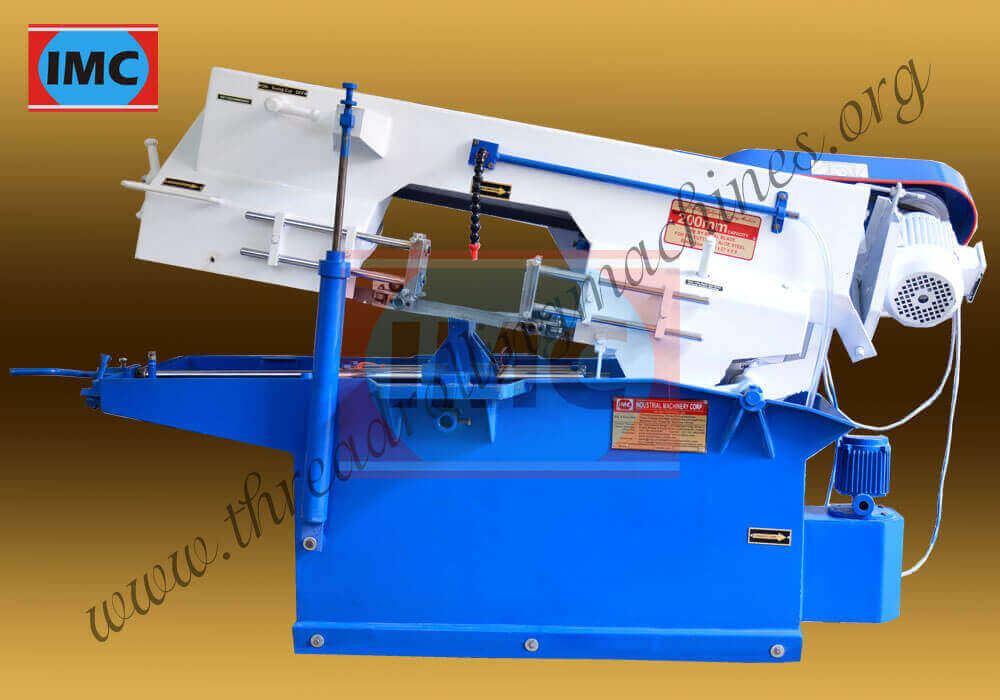

Bandsaw Machine

Industrial Machinery Corporation is a prominent name in the world of industrial machine manufacturing that has been manufacturing a wide range of industrial machines for the last 12 years. Since we have been in the business of industrial machine manufacturing for such a long time, we have gained all the necessary experience and expertise to build one of the most advanced Manual Bandsaw machines. Another reason why we are one of the most reliable Bandsaw Machine manufacturers is that we have kept the quality of our Manual Bandsaw Machine intact to sky height. And how have we managed to do it? By using the best raw materials, the latest technologies, the most advanced machines, and last but not least; the most experienced and skilled technicians to manufacture our machine.

VIEW SPECIFICATIONSAvailable Options

Specifications

The raw material that we use is drawn from the finest of resources and before getting into factories for final use, all the consignment of raw material is thoroughly checked by our quality vigilance team for any sort of flaw or imperfection. If found any, the raw material is immediately marked “unfit for use” and is separated from the rest of the raw material. Post-manufacture, not only the Bandsaw Machine but all our machines are again checked for any sort of production error. All the safety features and fittings are checked just to be sure that the Hydraulic Bandsaw Machine is absolutely safe for work.

The Bandaw Machine that we manufacture here at our manufacturing unit based in Ludhiana is equipped with an adjustable feed control device and has the competence to suit the various dissimilar requirements of the clients. All our machines are equipped with all standard safety measures to make this machine absolutely harmless and safe to work on. Being the most advanced machine, this machine is exceptionally easy to maneuver. These machines are designed to work continuously with pre-compression and main compression. The internal electrical wiring of these Manual Bandsaw Machines assures the flawless and long-lasting performance of these Bandsaw Machines. This Bandsaw Machine is known for its effective performance and facilitates different cutting operations in varied workshops along with its easy automation. Our Bandsaw Machine can be customized as per the requirements of the clients. Our hydraulic power Bandsaw machines are widely used in different industries because of their efficiency, fine cutting, and long-lasting trouble-free service.

Basic Components of a Manual Bandsaw Machine:

Blade: The bandsaw blade is a continuous loop of toothed metal that rotates around two wheels. It is the cutting element of the machine.

Blade Guides: These guides, positioned above and below the workpiece, help keep the bandsaw blade properly aligned during cutting, ensuring accurate and straight cuts.

Blade Tensioning System: The tensioning system maintains the proper tension on the bandsaw blade, crucial for preventing blade deflection and ensuring optimal cutting performance.

Blade Wheels: Two wheels, typically made of metal or rubber, rotate to move the bandsaw blade. One wheel is the drive wheel, connected to the motor, and the other is the idler wheel.

Table: The table provides a flat and stable surface for supporting the workpiece during cutting. It is adjustable for making different types of cuts and may have mitering capabilities for angled cuts.

Vise or Clamp: A vise or clamp secures the workpiece in place on the table, preventing movement during the cutting process.

Adjustable Blade Speed Control: Some manual bandsaw machines allow operators to adjust the blade speed based on the material being cut. Different materials may require different cutting speeds for optimal results.

Motor: The motor provides the power to rotate the bandsaw blade. It is typically adjustable to control the cutting speed.

Coolant System: In metal-cutting applications, a coolant system may be present to lubricate and cool the bandsaw blade, reducing friction and preventing overheating.

Safety Features: This includes components such as blade guards, emergency stops, and other safety mechanisms to ensure operator safety during operation.

Steps for Operating a Manual Bandsaw Machine:

Blade Installation: Make sure the bandsaw blade is correctly installed and properly tensioned according to the manufacturer's guidelines.

Adjust the Table: Set the table at the desired height and angle for the specific cut you are making. Ensure it is securely locked in place.

Select Blade Speed: Adjust the blade speed based on the material being cut. Refer to the machine's manual for recommended speed settings.

Secure the Workpiece: Use the vise or clamp to securely hold the workpiece in place on the table. Ensure it is stable and won't move during cutting.

Start the Machine: Turn on the bandsaw machine, allowing the blade to reach its full speed before making a cut.

Feed the Workpiece: Gently feed the workpiece into the rotating blade, following the cutting line. Avoid forcing the material through; let the blade do the cutting.

Monitor the Cut: Keep an eye on the cutting process, making any necessary adjustments to the feed rate or other settings for optimal results.

Complete the Cut: Once the cut is complete, turn off the machine and allow the blade to come to a complete stop before removing the cut material.

Maintenance: Perform routine maintenance tasks, such as blade inspection, tension adjustment, and lubrication, to keep the bandsaw machine in good working condition.

Always follow the manufacturer's guidelines and safety instructions when operating a manual bandsaw machine. Regular maintenance and proper operation contribute to the longevity and efficiency of the machine.

| Model (unit) | HM-175 | HM-200 | HM-250 | HM-300 | HM-350 | HM-400 | HM-450 |

| Capacity(mm) | 175mm | 200mm | 250mm | 300mm | 350mm | 400mm | 450mm |

| Round(mm) | 175mm | 200mm | 250mm | 300mm | 350mm | 400mm | 450mm |

| Square(mm) | 150x150 | 150x150 | 200x200 | 250x250 | 300x300 | 350x350 | 400x400 |

| Drive Motor (HP/ RPM) | 0.5/1440 | 1/1440 | 1.5/1440 | 2/1440 | 2/1440 | 2/1440 | 3/1440 |

| Coolant Pump (HP/ Volts) | 0.15/440 | 0.15/440 | 0.15/440 | 0.15/440 | 0.15/440 | 0.15/440 | 0.15/440 |

| Blade Speed (Meter / Minute) | 25/30/40 | 20/35/55/75 | 20/35/55/75 | 35/55/75 | 35/55/75 | 35/55/75 | 35/55/75 |

| Bandsaw Blade (mm) | 2515x19x0.9 | 3000x27x0.9 | 3000x27x0.9 | 3760x27x0.9 | 4100x27x0.9 | 4420x34x1.1 | 4700x34x1.1 |

| Floor Space LxWxH (mm) | 1500x570x870 | 1630x580x895 | 2000x600x900 | 2400x830x1050 | 2550x830x1050 | 2650x830x1200 | 2800x830x1250 |

| Net Weight (kg) approx. | 250 kg | 322 kg | 400 kg | 651 kg | 600 kg | 650 kg | 700 kg |

| Packed Weight (wooden) approx. | 330 kg | 400 kg | 500 kg | 731 kg | 800 kg | 850 kg | 910 kg |