Hydraulic Surface Grinder Machine

Industrial Machinery Corporation has been a well-known name in the field of manufacturing Surface Grinder Machines and Hydraulic Surface Grinders. We stepped into this business in 2011 and since then ...

VIEW MORE

Industrial Machinery Corporation was formed in the year 2011 with the motive of designing, manufacturing and supplying industrial machines to the world and through our best quality services and products get a stiffly placed name in the world of industrial machine manufacturing. In all these 7 years we have gained a huge success in our motives and have a list of industrial machines that we have expertise in building. Today there are clients from entire world for our industrial machine but from countries like USA, Mexico, Brazil, Venezuela, Ecuador, Korea, Turkey, India, UAE, Malaysia, Indonesia, Iran, Uzbekistan, Kazakhstan, Vietnam, Cambodia, Thailand, Syria, Jordan, Pakistan, Kuwait, Iraq, Nigeria, Egypt, Sudan, Ethiopia, Kenya, Tunis, South Africa, Ukraine, Russia, Belarus, Italy, Belgium, Macedonia, Greece and many others have been continuously buying our machines. If you are in search of a good industrial machine and especially Pipe End Facing Machine manufacturer that you need not go anywhere than industrial machine corporation. Our Pipe End Facing Machine is widely known for its qualities like durability, effectiveness, efficiency, toughness and portability. Because of these in-built characteristics, we are acknowledged as the best Pipe End Facing Machine and Pipe Chamfering Machine India.

VIEW SPECIFICATIONSA Pipe End Facing Machine is basically used to chamfer and for debarring of pipes before they are sent for galvanizing and threading process. Using our Pipe End Facing Machine, a user can chamfer the pipe from in, out and front using the three different tools. The pipe in our Pipe End Facing Machine remains motionless and the facing head rotates. In manual procession of a Pipe End Facing Machine, the slide moves towards facing head for chamfering process.

Listed below are the silent features of our Pipe End Facing Machine:

Below are the names of various parts that assemble to make one Pipe End Facing Machine:

Mentioned below, are the characteristics of our Pipe End Facing Machine that makes it distinguished from machines from other manufacturers:

| Model No. | IMC-EM- 1/2" to 1.1/2" | IMC-BM-1/2" to 4" |

| Min. Dia of Pipe to be Chamfered | 1/2" N.B. Pipe | 1/2"" |

| Max. Dia of Pipe to be Chamfered | 1.1/2" | 4" |

| Cutting Tools Required (HSS 10% Cobalt) | 3/8" | 3/8" |

| Number of Spindle Speeds | Two nos. | Four nos. |

| Range of Spindle Speeds | 37 to 64 RPM | 68 to 180 RPM |

| Main Motor | 3 H.P. 1440 RPM | 3 H.P. 1440 RPM |

| Approx. Wt. of the Machine | 750 Kgs. | 1100 Kgs. |

Industrial Machinery Corporation has been a well-known name in the field of manufacturing Surface Grinder Machines and Hydraulic Surface Grinders. We stepped into this business in 2011 and since then ...

VIEW MORE

Buffing machines are generally used to improve the metal surface. Be it automobiles, machines or even glass, Buffing machines to expel the dull outlook of the metal surfaces and give it a refined new ...

VIEW MORE

We, "Industrial Machinery Corporation" established in 2011, have been recognized as a coveted supplier of a wide assortment of Threading Machine, Bar Threading Machine, Bolt Threading Machine, Rod Thr ...

VIEW MORE

Industrial Machinery Corporation has uniquely positioned ourselves as a dependable firm, engaged in manufacturing and supplying a commendable array of Resharpening Machine. These Tools and Taps Reshar ...

VIEW MORE

From the year 2011 in the industry have made us strong and provided us with endless opportunities, which has enabled us to establish ourselves as one of the renowned manufacturers and exporting organi ...

VIEW MORE

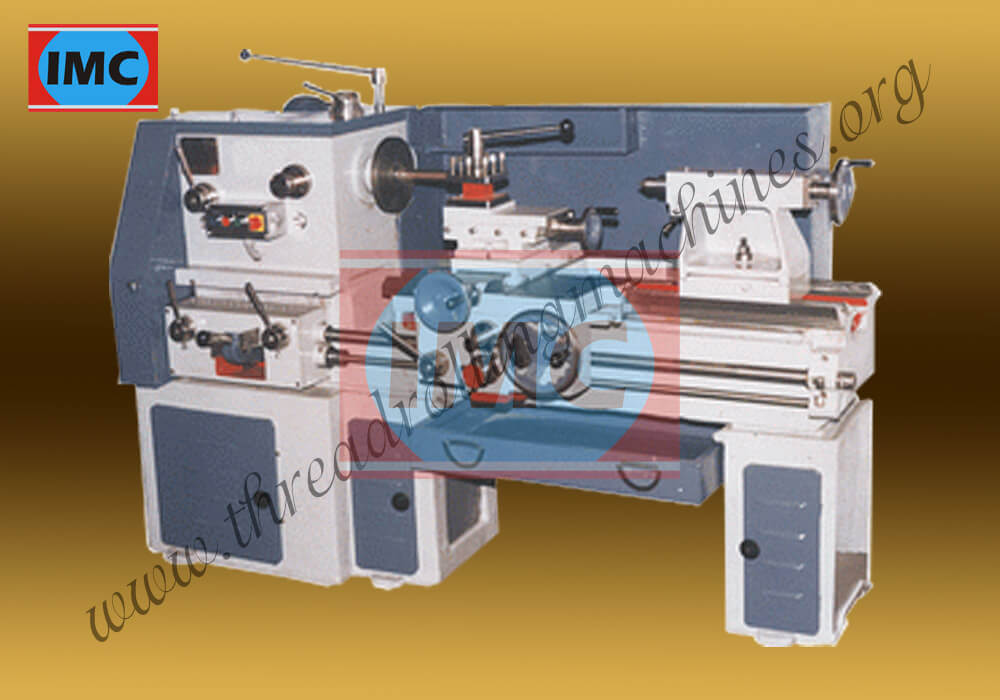

While there are a number of lathe machines available in the market today, there are some that are specialized and can be used only for specific purposes. These are used for specific purposes and are ...

VIEW MORE