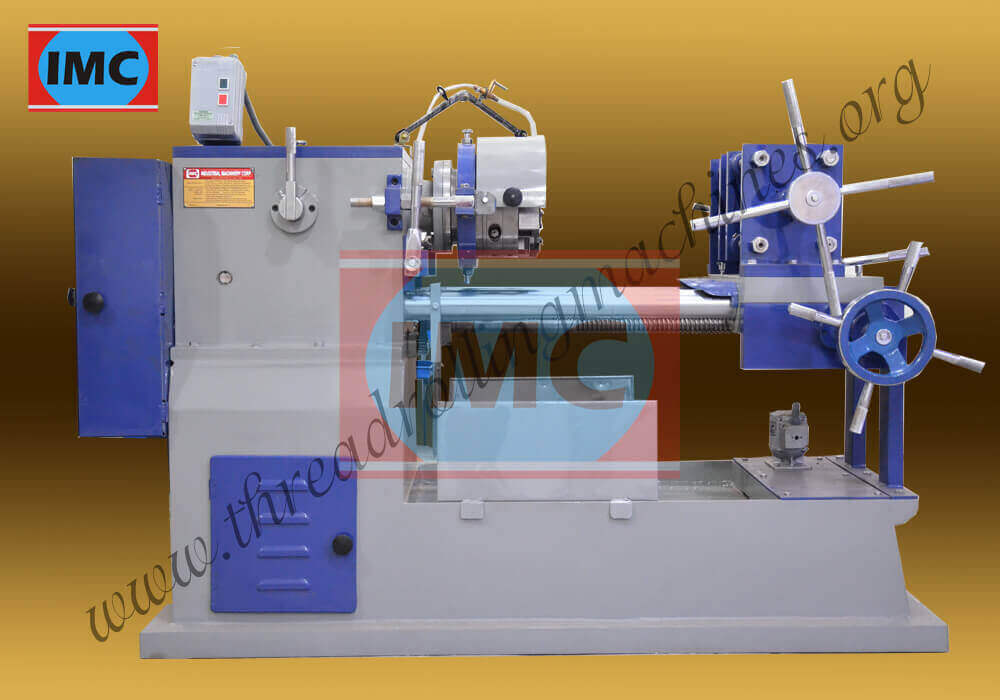

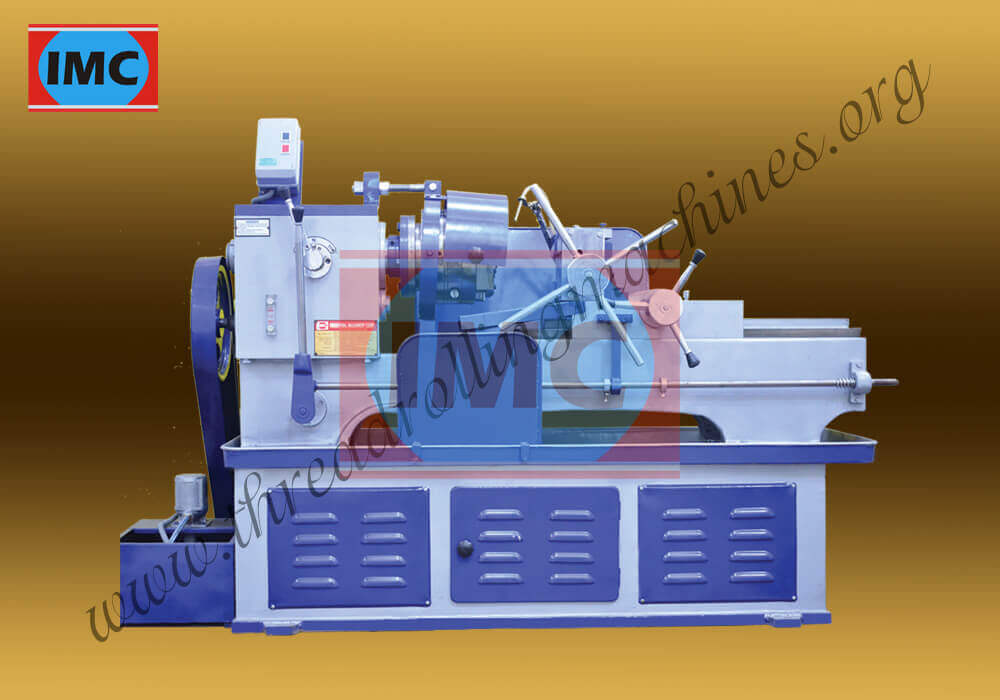

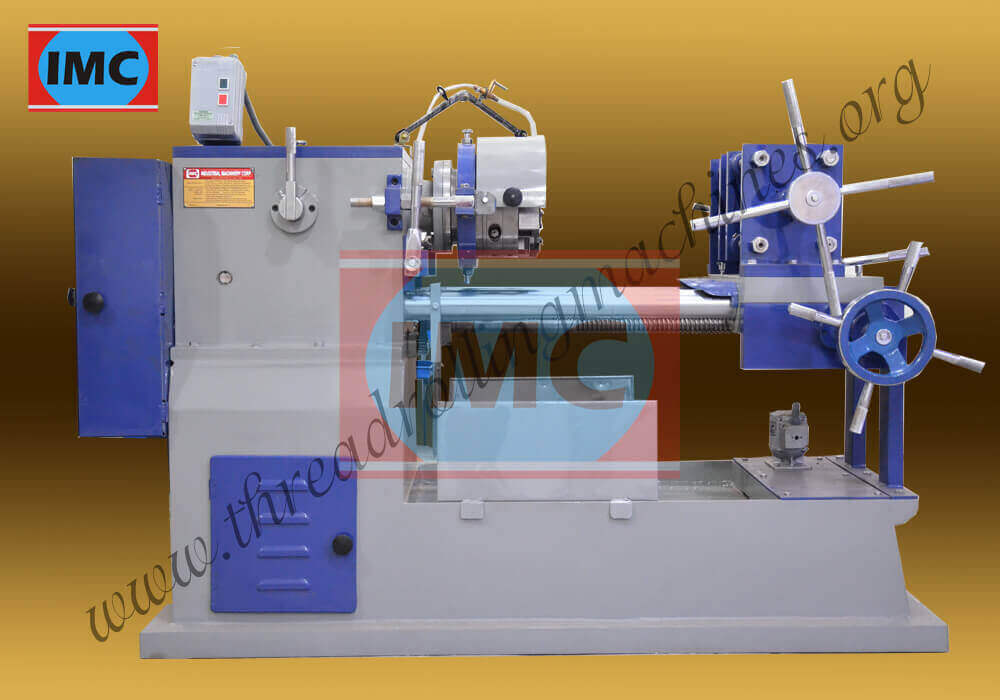

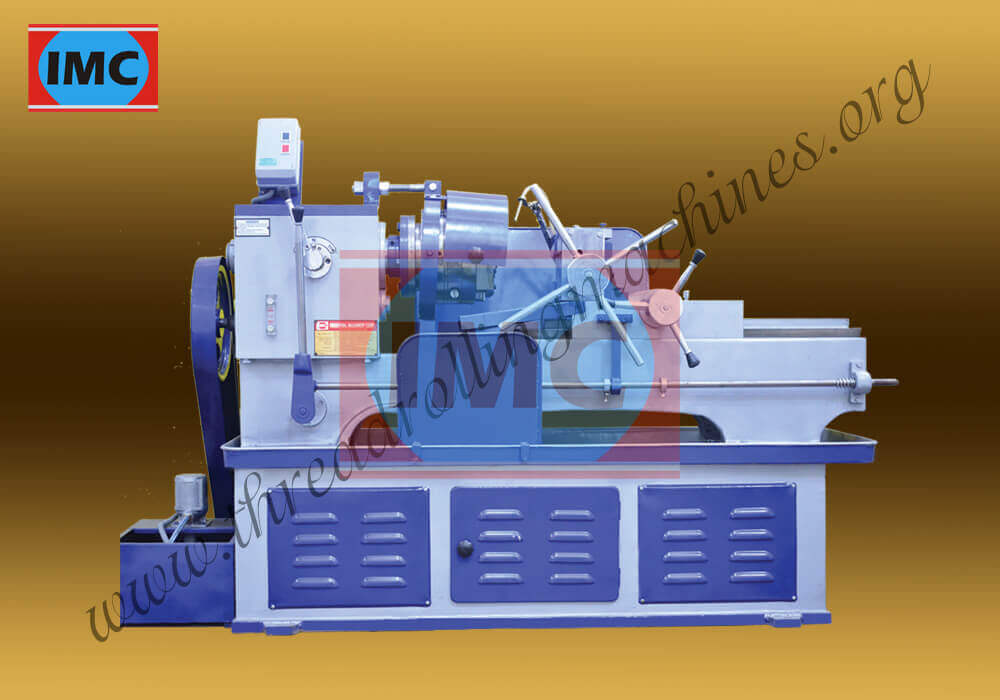

Rebar Threading Machine

Being in the business of industrial machine manufacturing for more than 12 years, we would advise all the buyers of the Rebar Threading Machine to have a detailed conversation on what customization you actually require in your rebar threading machine. To get the Rebar Threading Machine as per your customized requirements, it is always best to buy this machine from an experienced bar threading company in India and when it comes of best, there is no name ahead of industrial machinery corporation. With its manufacturing unit based in Ludhiana, we have more than ten years of experience in making Rebar Thread Cutting Machines. We have been serving all our clients with the best industrial machines and not only this; we have been giving exceptional after-sales service, in case, any of our machines faces any technical problem which is very rare. We have every now and then, proved that the Rebar Thread Cutting Machine built by us is the best in the lot and the reason behind this is that we make this Machine with international standards and keep in mind, all the international trends and parameters. Prior to sending the finished machine to the customer, we check our Machine for its durability, strength, robustness, efficiency, and versatility. Once found perfect in all these aspects of performance, only then, the machine is forwarded to be delivered.

VIEW SPECIFICATIONSAvailable Options

Specifications

As we have been in this business for more than 12 years, we have all the expertise and skills related to technical knowledge which is required to make our Rebar Threading Machine unbeatable and the most influential Rebar Threading Machine in the market. While manufacturing this Machine, we ensure that only that raw material is used which has surpassed various quality checks before entering into our manufacturing unit. For all these 12 years of being in business, we have always kept our production standards very high and ensured that there is no flaw in the entire process.

A Rebar Threading Machine is used in tool-rooms and factories to cut external threads on the bars and this machine runs using the chasing method. In the chasing method, the Bar Threading Machines make the bar stay unmoved in one place and make the die head rotate around and create fine threads. Bar Thread Cutting Machines work best with HSS Tangential chasers and can cut a wide variety of threads. But the main factor influencing this variety created by Rebar Thread Cutting Machines is what type of cutter is being used at that time on this machine.

Below is the list of cuts that our Rebar Thread Cutting Machines manufactured at our unit based in Ludhiana can cut:

- Matric

- BSP

- BSPT

- NPT

- UNF

- UNC

- BSW

- Acme Threads

- B.S.F

Here is the list which contains the names of various parts of Rebar Thread cutting Machines made by industrial machinery corporation at Ludhiana based unit:

- Base

- Head Stock

- Saddle

- Bed or Pillar Type Clamping Vice

- Die Head

Rebar Threading Machine Specifications:

| MODEL | 1/4" TO 1" (BED TYPE) | 3/8" TO 1.1/2" (BED TYPE) | 1/2" TO 2.1/2" (BED TYPE) |

| Saddle Movement | 10" | 13" | 22" |

| Spindle Speed Range | 75-140 | 75 -140 | 45 - 90 |

| Number of Spindle Speed | 2 | 2 | 2 |

| Threading Capacity | 1/4" to 1" | 3/8" to 1.1/2" | 1/2" to 2.1/2" |

| Production per Hour | 60-80 | 60-80 | 70-90 |

| H.P. Required | 3 H.P. | 3 H.P. | 7.5 H.P. |

| Lead Screw | Optional | Optional | Optional |

| Weight (KG) Approx. | 500 | 550 | 990 |

Rebar Thread Cutting Tangential Chaser

IMC Tangential Chasers are manufactured from imported High-Speed Steel which must pass exacting metallurgical standard. Experienced heat treatment with the automatically imported heat treatment plant and imported Testing equipment's, assures that they will perform satisfactorily in service and produce quality threads within the tolerance for which they ware intended.

IMC Chaser is interchangeable. If one Pc. Of a chaser, the set is damaged & is beyond use. Then same No. pc. of the other chaser set lying in stock may be used and there will not be any difference in threading performance and the damaged set can be replaced without the necessity of replacing the entire set.

Read More..