Mig Welding Machine

Mig Welding Machine which means Metal Inert Gas Welding and it is also known as (GMAW) Gas Metal Arc Welding which is broadly used in shipbuilding, auto industries as well as in heavy and light fabric ...

VIEW MORE

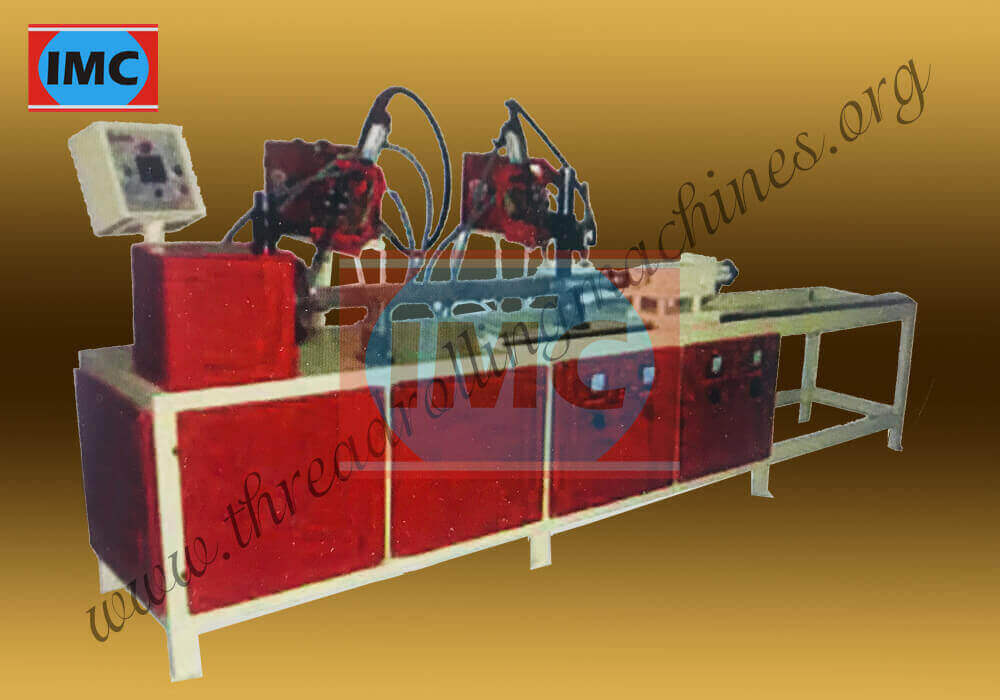

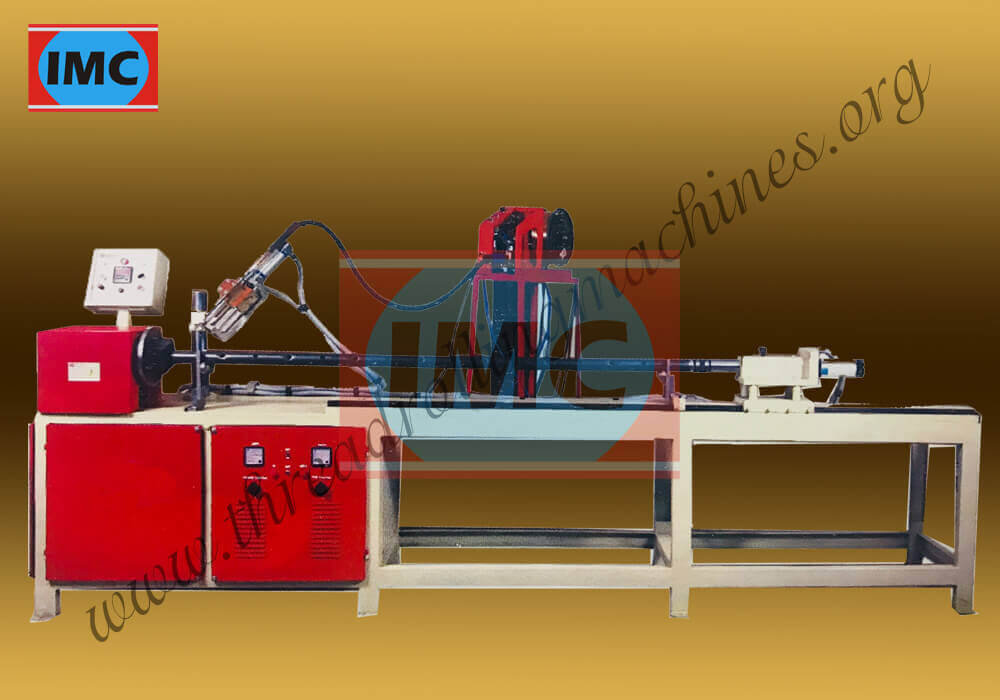

Industrial Machinery Corporation (IMC) introduces the Scaffolding Prop Welding Machine - Double-Sided, a state-of-the-art solution designed to streamline and enhance the welding process for scaffolding props. Meticulously crafted for efficiency and precision, this machine offers double-sided welding capabilities, ensuring a robust and reliable connection for scaffolding structures.

Industrial Machinery Corporation (IMC) introduces the Scaffolding Prop Welding Machine - Double-Sided, a state-of-the-art solution designed to streamline and enhance the welding process for scaffolding props. Meticulously crafted for efficiency and precision, this machine offers double-sided welding capabilities, ensuring a robust and reliable connection for scaffolding structures.

Key Features:

Double-Sided Welding: IMC's Scaffolding Prop Welding Machine excels in double-sided welding, ensuring a strong and symmetrical bond on both sides of the scaffolding props for enhanced structural integrity.

Automated Welding Process: Equipped for fully automated welding processes, the machine reduces manual labor, increases efficiency, and ensures consistency in welding quality.

Versatile Compatibility: Designed to weld a variety of scaffolding props, the machine accommodates different sizes and specifications, providing flexibility in scaffolding design.

Programmable Control Panel: The user-friendly control panel allows for easy program selection, parameter adjustment, and quick adaptation to various welding configurations.

Precise Welding Technology: Benefit from the precision welding capabilities of our machine, ensuring accurate and reliable connections for each scaffolding prop.

Sturdy Construction: Built with a robust frame and durable components, the machine guarantees stability and longevity in continuous double-sided welding operations.

Efficient Welding Mechanism: Equipped with efficient welding mechanisms, our machine ensures optimal welding processes, contributing to the overall durability of scaffolding structures.

Quality Assurance: IMC prioritizes the quality of the welding process, ensuring each connection is secure, meeting industry standards for safety and reliability.

Operating Steps:

Material Placement: Position the scaffolding prop in the machine, ensuring proper alignment for double-sided welding.

Program Selection: Utilize the programmable control panel to select the specific welding program and parameters based on the scaffolding prop specifications.

Automatic Double-Sided Welding: Activate the machine, and witness the automated double-sided welding process. The machine seamlessly welds both sides of the scaffolding prop with precision and efficiency.

Quality Check: Conduct periodic quality checks during the welding process to ensure the integrity of each weld, maintaining consistency and reliability.

Unloading Processed Scaffolding Props: Once the welding cycle is complete, safely unload the finished scaffolding props with double-sided welds for use in your construction projects.

IMC's Scaffolding Prop Welding Machine - Double-Sided is a game-changer in scaffolding construction, providing automated and precise welding solutions for enhanced structural durability. Trust IMC for welding machinery that meets the demands of modern construction practices, ensuring safety and reliability in every joint.

Mig Welding Machine which means Metal Inert Gas Welding and it is also known as (GMAW) Gas Metal Arc Welding which is broadly used in shipbuilding, auto industries as well as in heavy and light fabric ...

VIEW MORE

Industrial Machinery Corporation is an ISO certified organization, engaged in manufacturing and exporting of Threading Machine, Thread Rolling Machine, Scaffolding Welding Machine, Rebar Coupler Machi ...

VIEW MORE

Today, the importance of Inner Prop Welding Machines is constantly increasing in auto industries, light and heavy fabrication work. We used best quality raw material, standardized advanced technology ...

VIEW MORE

Industrial Machinery Corporation provides our clients with a comprehensive range of Base Jack Welding Machine, which is dimensionally accurate and wears & tear resistant. These are corrosion-resistant ...

VIEW MORE

Industrial Machinery Corporation is the well known standardized company which engaged in exporting as well as in the manufacturing of Scaffolding machines like Horizontal Ledger Welding System, Cup Lo ...

VIEW MORE

Industrial Machinery Corporation has been in the business of manufacturing welding machines for more than a decade now. By being in this business for so long, we have acquired a vast experience and ex ...

VIEW MORE

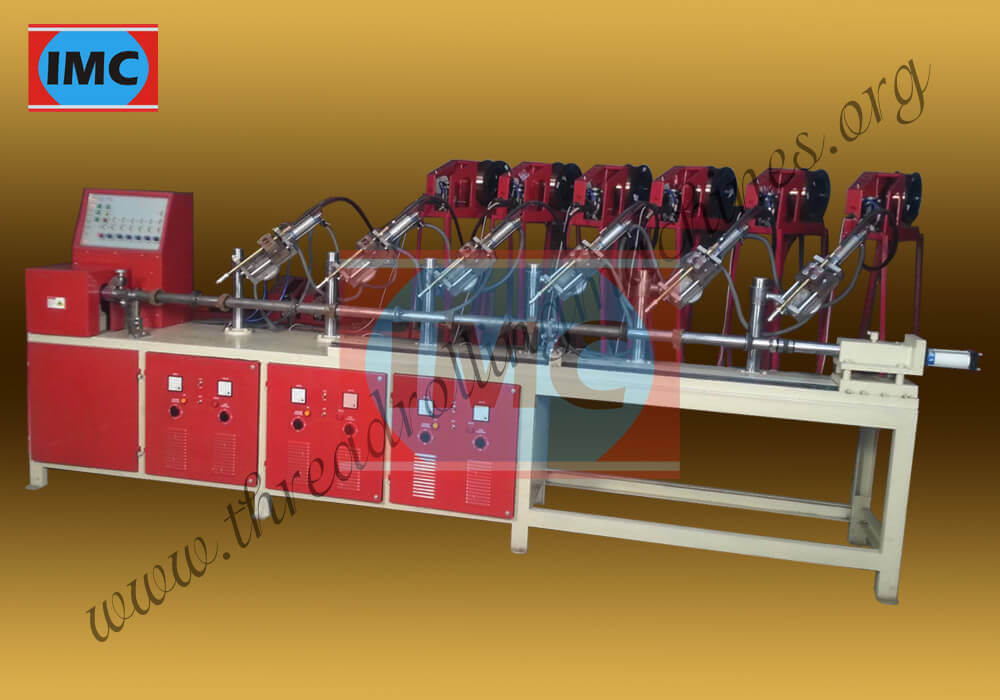

The main feature of this Automatic Cuplock Welding System is mostly used to weld six cups at the time with the pipe on a tagging fixture. Cuplocks is one of the main components of this machine which a ...

VIEW MORE

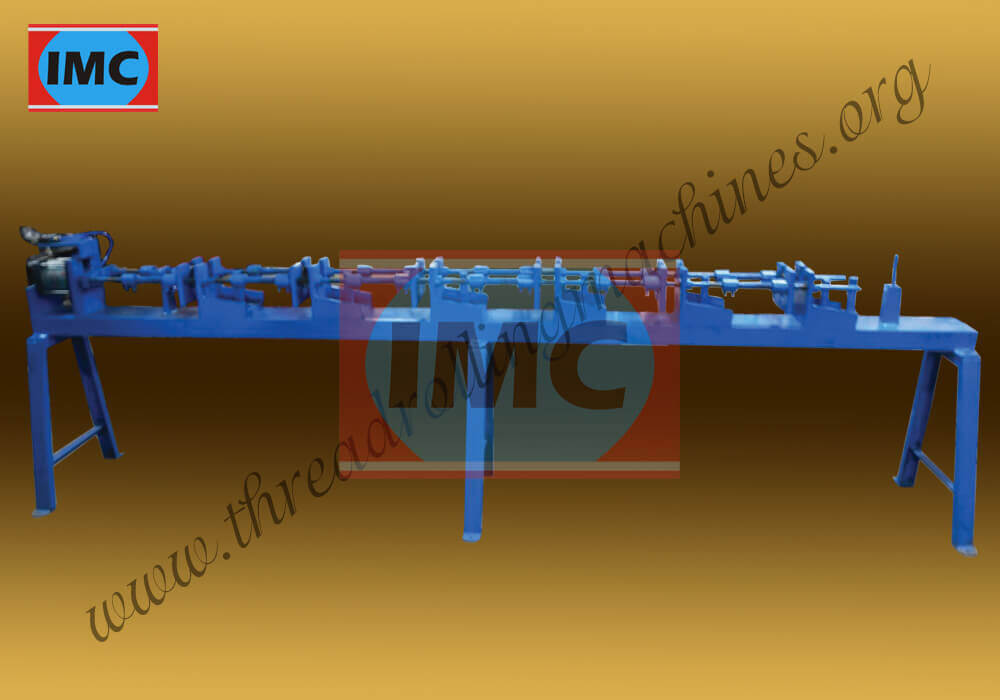

Industrial Machinery Corporation (IMC) presents the Scaffolding Pipe Punching Machine, a state-of-the-art solution designed to streamline the hole-making process in scaffolding pipes. Meticulously cra ...

VIEW MORE

Industrial Machinery Corporation (IMC) proudly introduces the Scaffolding Prop Nut Cup Handle Welding Machine, a cutting-edge solution designed to revolutionize the welding process for prop nut cup h ...

VIEW MORE

Revolutionize your scaffolding production with Industrial Machinery Corporation's (IMC) Automatic Scaffolding Cup Sleeve Nut Handle & G Pin Making Machine. Designed for efficiency and precision, this ...

VIEW MORE