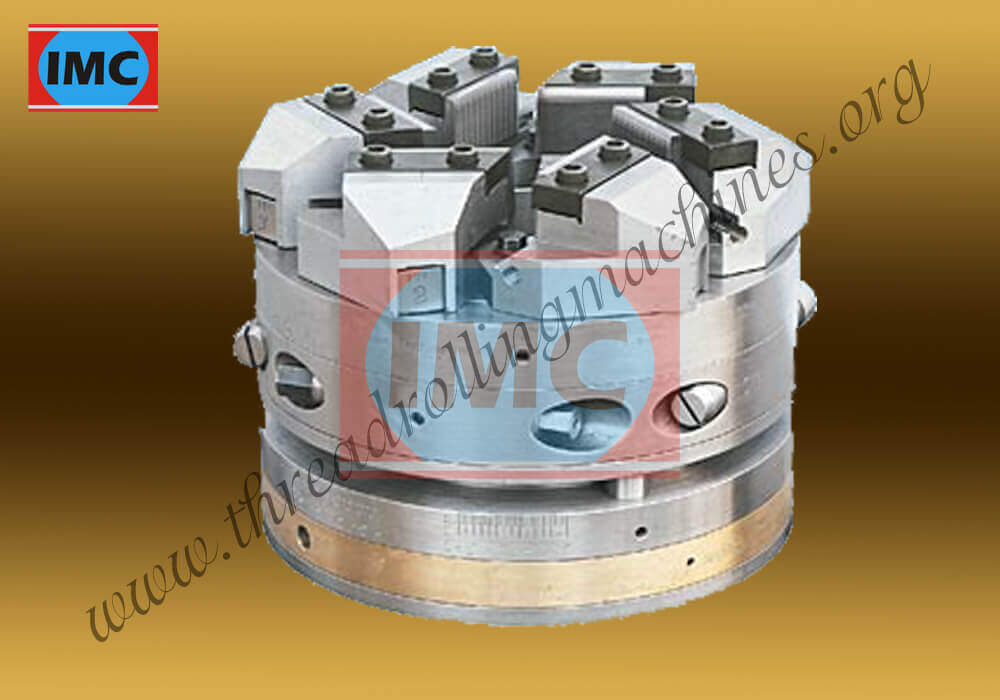

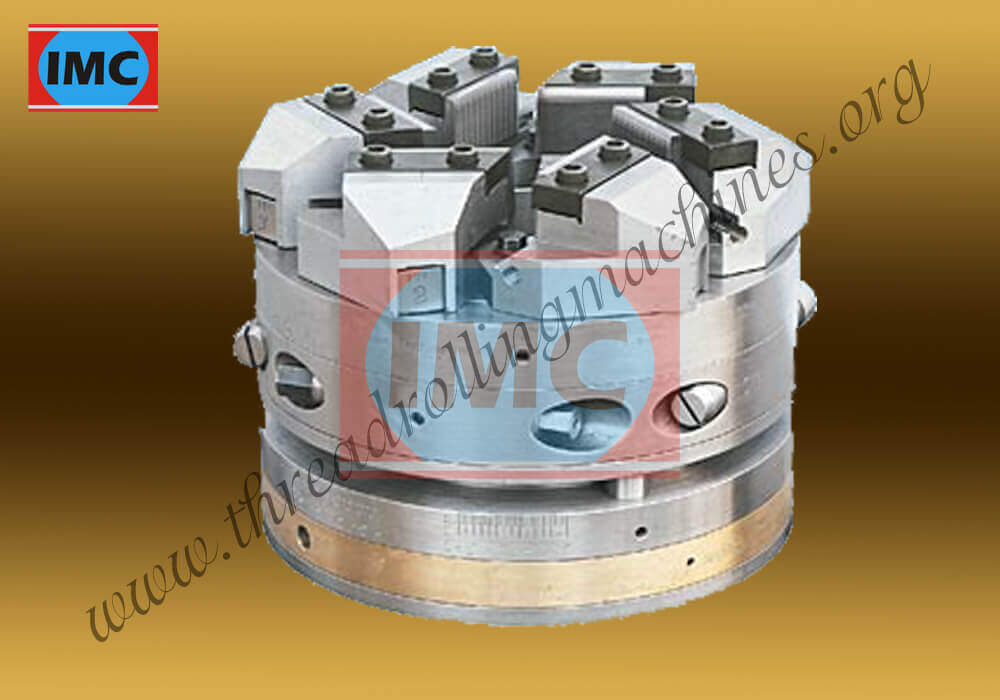

Lanco Type Threading Die Head

Since our formation in 2011, we have been busy manufacturing a wide range of industrial machines and have gained a huge reputation in it. So much, that today we are reckoned as one of the most influen ...

VIEW MORE

IMC Threading taps are especially designed tools used to cut the female portion of a mating pair of metal fasteners. A Threading Tap removes material from a pre-drilled or punched hole. The result produces threads within the drilled hole. The cutting edges at the front of a tap remove material from the workpiece. The chips are stored in the flutes, or pushed forward in front of the tap, or are drawn up along the flutes, removing the chips and cutting fluids from the hole.

A chamfer is a tapered portion at the front end of the tap. Both the chamfered portion and the first full thread beyond the chamfer produce the finished thread of the part. Industrial Machinery Corporation manufactured Threading Taps as per industry standards and stands high on parameters of quality and durability.

VIEW SPECIFICATIONSA chamfer is a tapered portion at the front end of the tap. Both the chamfered portion and the first full thread beyond the chamfer produce the finished thread of the part. Industrial Machinery Corporation manufactured Threading Taps as per industry standards and stands high on parameters of quality and durability.

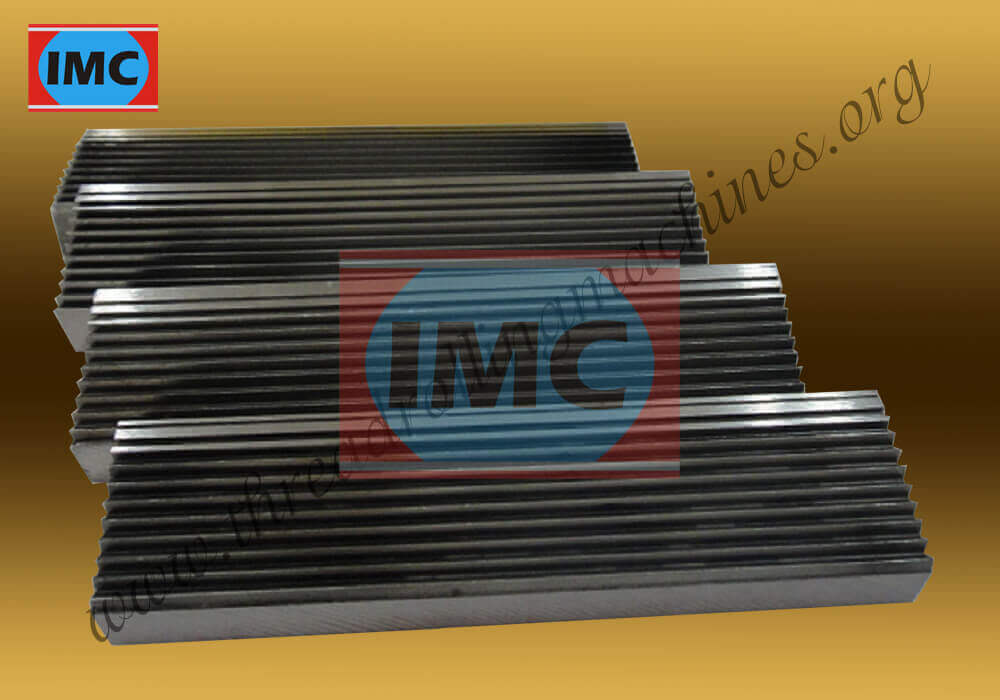

Threading is divided into two types, internal and external.Internal threading is done by using a tool called a TAP in a hole drilled to a specific diameter for the thread size and pitch you want to cut. External threads, such as for bolts and studs, are made by using a tool called a DIE, which is applied to a specific diameter of the rod for the size and pitch of the threads you want to cut.

Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A Threading Tap is used to cut or form the female portion of the mating pair (e.g., a nut). A die is used to cut or form the male portion of the mating pair (e.g., a bolt). The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading. Both tools can be used to clean up a thread, which is called chasing.

A Threading Tap cuts a thread on the inside surface of a hole, creating a female surface which functions like a nut.

Machine TappingInternal Threading Machine is used tool tap for internal threading. Machine tapping is faster, and generally more accurate because human error is eliminated.

Although in general machine tapping is more accurate, tapping operations have traditionally been very tricky to execute due to frequent tap breakage and inconsistent quality of tapping.

The Threading Taps offered by Industrial Machinery Corporation. Different types of Threading Tap can be used for internal threads such as BSW, NPT, UNF, METRIC, UNC, ACME, BSF Threads etc. Industrial Machinery Corporation will also offer the benefit of customization.

"

Since our formation in 2011, we have been busy manufacturing a wide range of industrial machines and have gained a huge reputation in it. So much, that today we are reckoned as one of the most influen ...

VIEW MORE

For 7 years, we have been producing the best quality industrial machines and satisfying our clients ranging from not only India but many foreign countries. Since we have been in this business, we have ...

VIEW MORE