Wire Straightening And Cutting Machine

Industrial Machinery Corporation is one of the prominent companies in the market that offers you latest equipment’s for the high production. We manufacture Wire Straightening and Cutting Machine 's with natural and best quality raw material. Our Wire Straightening and Cutting Machine is well prepared to cut the wire effectively as per desired length. Wire straightening consist a straightening wheel which has more strength, using rotating handle it imposes the pressure upon the steel bar. When the steel bar is straightened, internal force starts get eliminated during the operation. As a result, for the uniform landing and lifting, a power motor based pressure unit is most convenient.

VIEW SPECIFICATIONSAvailable Options

Specifications

The main characteristics of this Wire Straightening Cutting Machine are a modern design, low maintenance, and high throughput. These machines are available in various capacities that depend upon the thickness, weight, speed, and length of the wire.

In addition to this, it is more effective, efficient and easy to use for longer life. We always used the latest and advance technology for the manufacture of these cutting machines. With the help of Wire Straightening and Cutting Machine 's, we cut a different variety of materials such as Mild steel, EN8, SS 316, SS 304, SS 202, Brass, Copper, Rebar, Aluminum and Spring steels. These machines are powerful which is fixed with straightening device as well as with cutting device that makes a perfect machine for the correct operation. Mostly these machines are used in automobile industries, Electrical industries, Metal processing industries and many other types of metal fabrication work. These machines are manufactured in our Ludhiana Unit under very strict quality control. Moreover, we always fulfill the requirements of the customers as providing the high-quality machinery within the budget also.

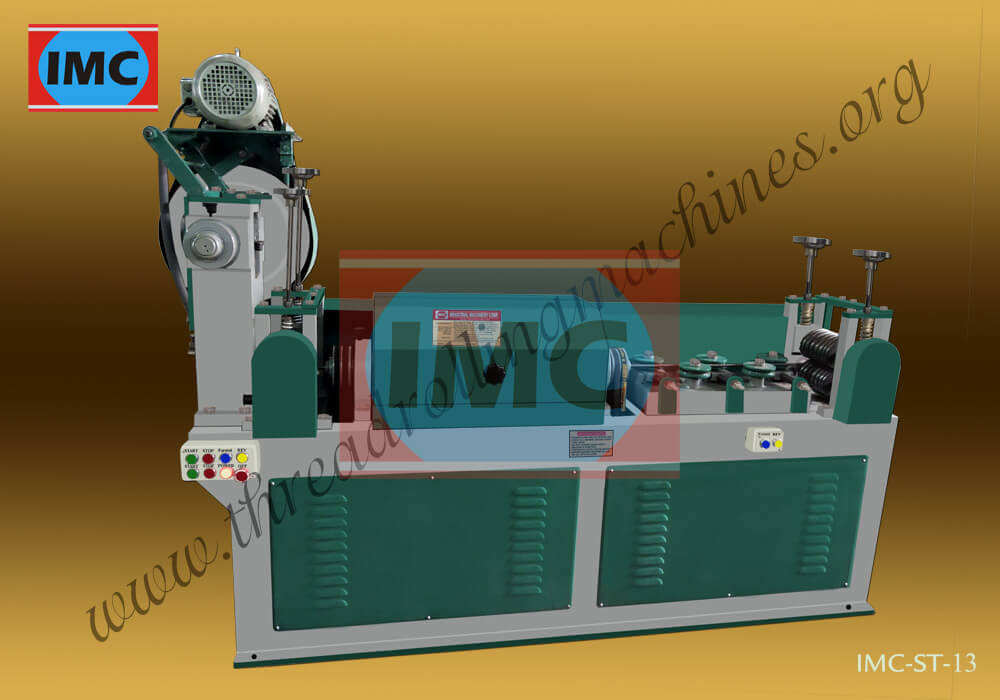

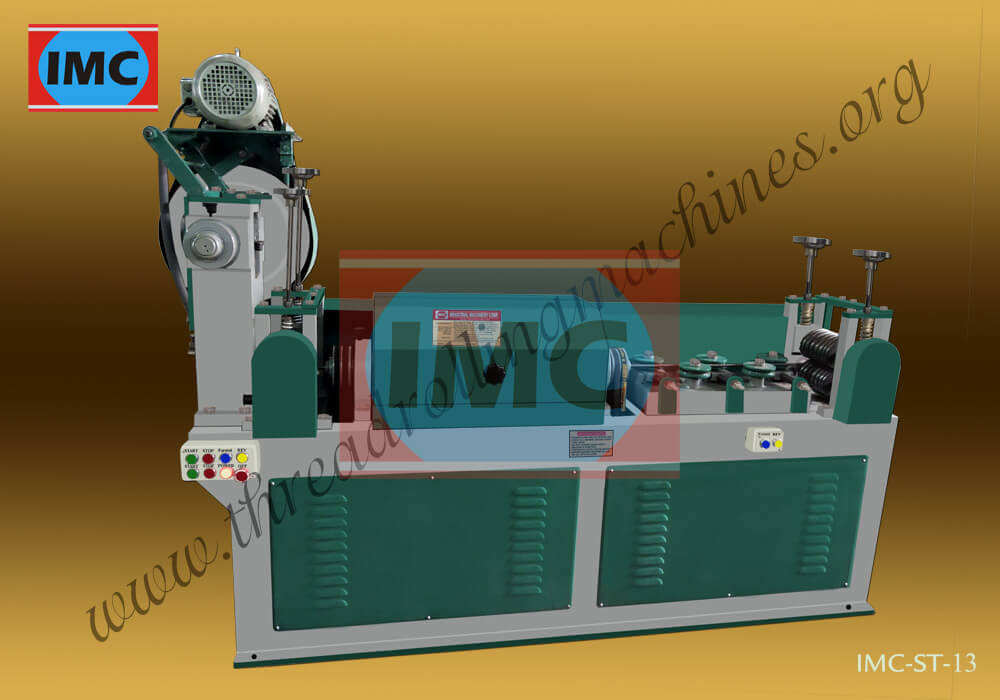

| Specifications : | IMC-ST-7 | IMC-ST-8 | IMC-ST-10 | IMC-ST-12 | IMC-ST-13 |

| In Thickness of wire | 2 to 7mm | 3 to 8mm | 4 to 10mm | 4 to 12mm | 3 to 13mm |

| In Length of wire to be cut automatically | As per Requirement | As per Requirement | As per Requirement | As per Requirement | As per Requirement |

| Feeding capacity per min. | 70" feet | 70" feet | 70" feet | 60" feet | 60" feet |

| Power of motor H.P. | 3 H.P. | 5 H.P. | 5 H.P. | 10 H.P. | 10 H.P. |

| Required R.P.M. | 1440 | 1440 | 1440 | 1440 | 1440 |

| Approx. Weight in Kg. | 410 | 460 | 550 | 1000 | 1200 |

| Floor space required | 42"x18" | 48"x20" | 52"x20" | 60"x22" | 82"x22" |

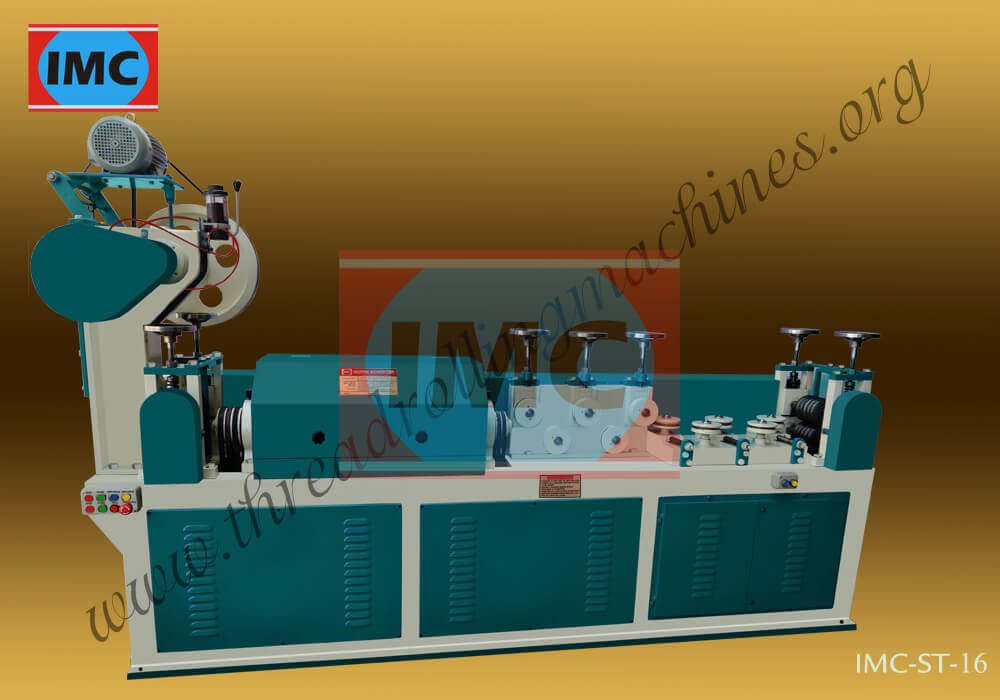

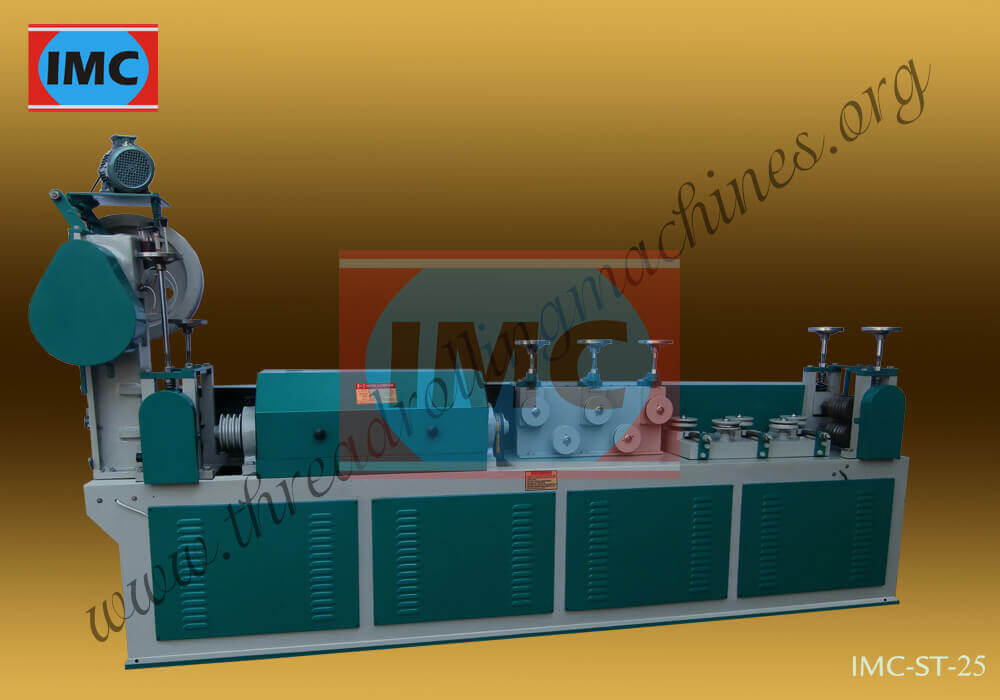

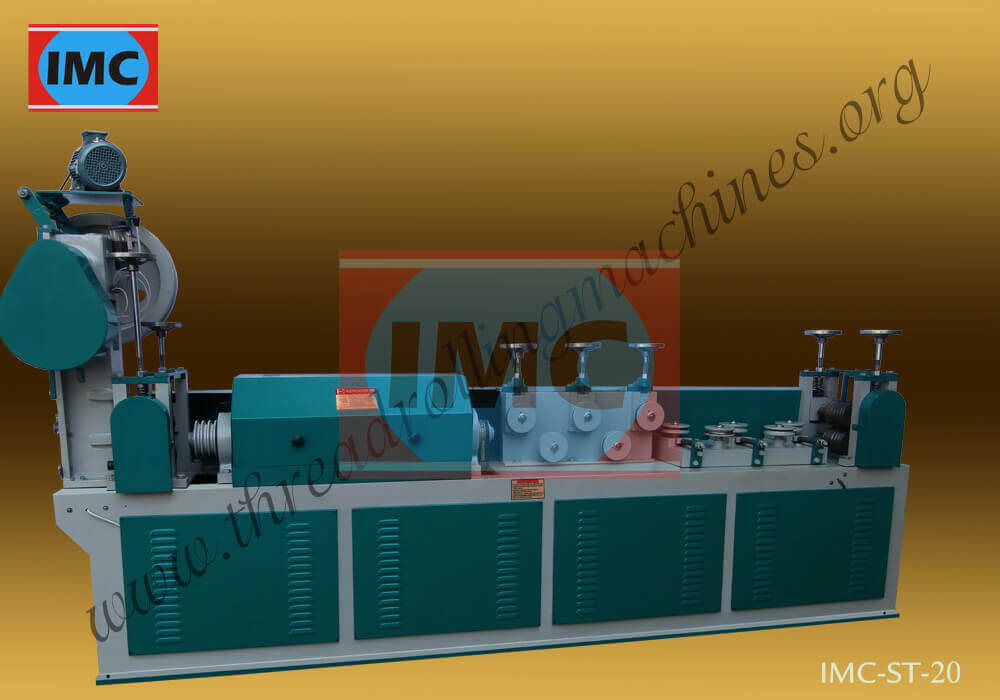

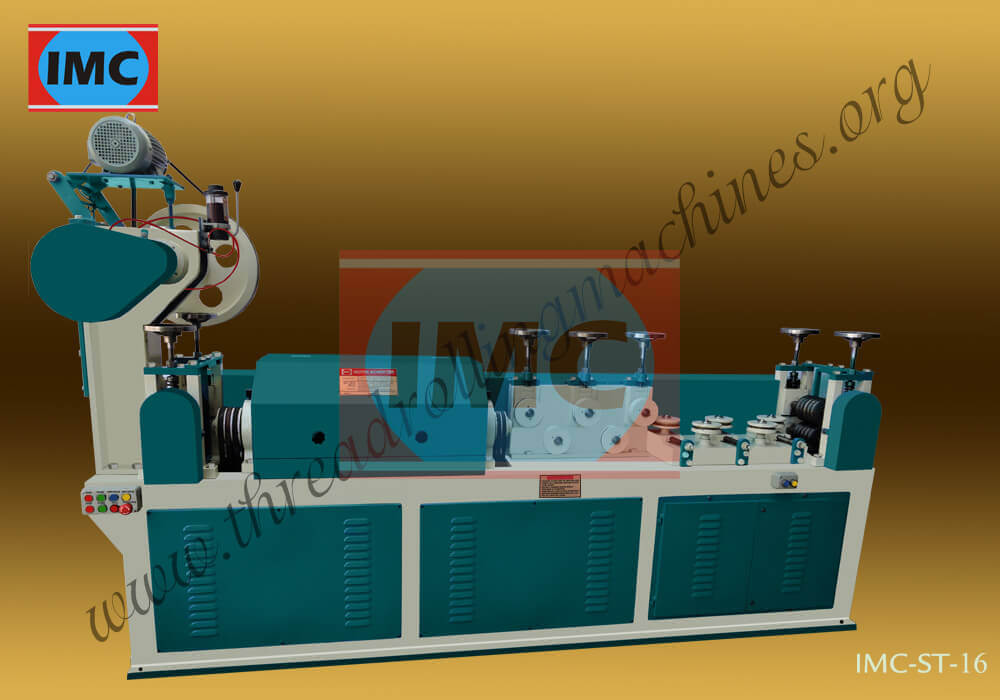

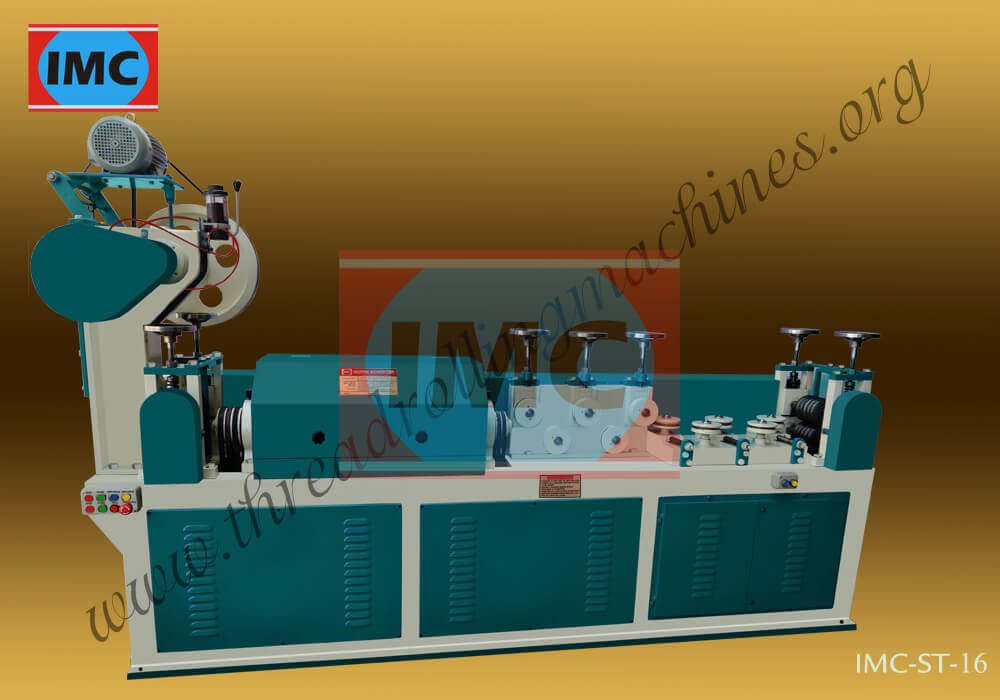

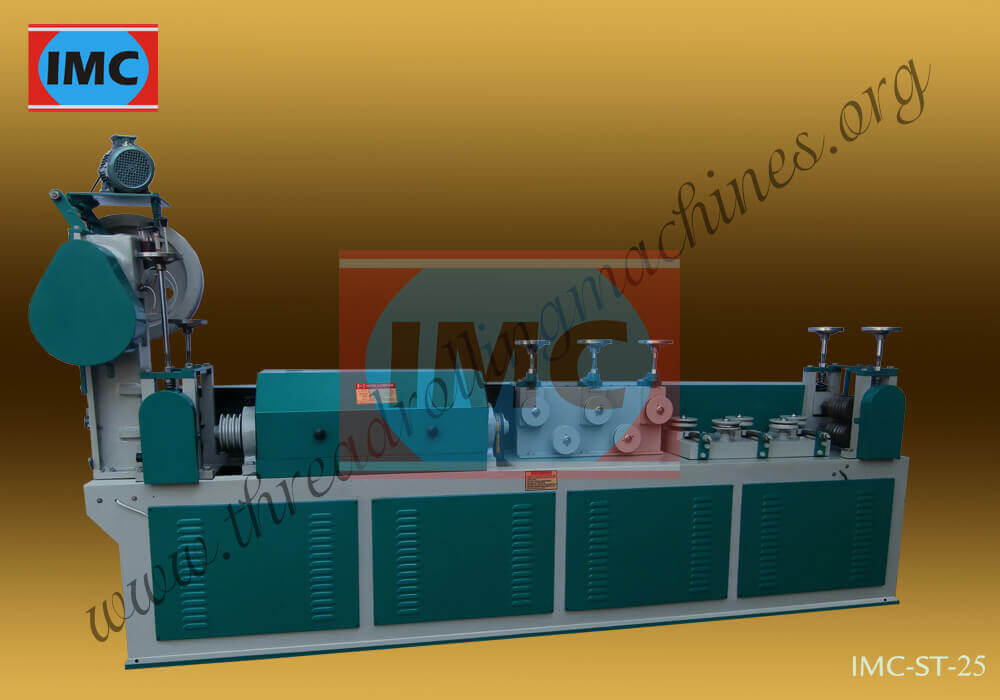

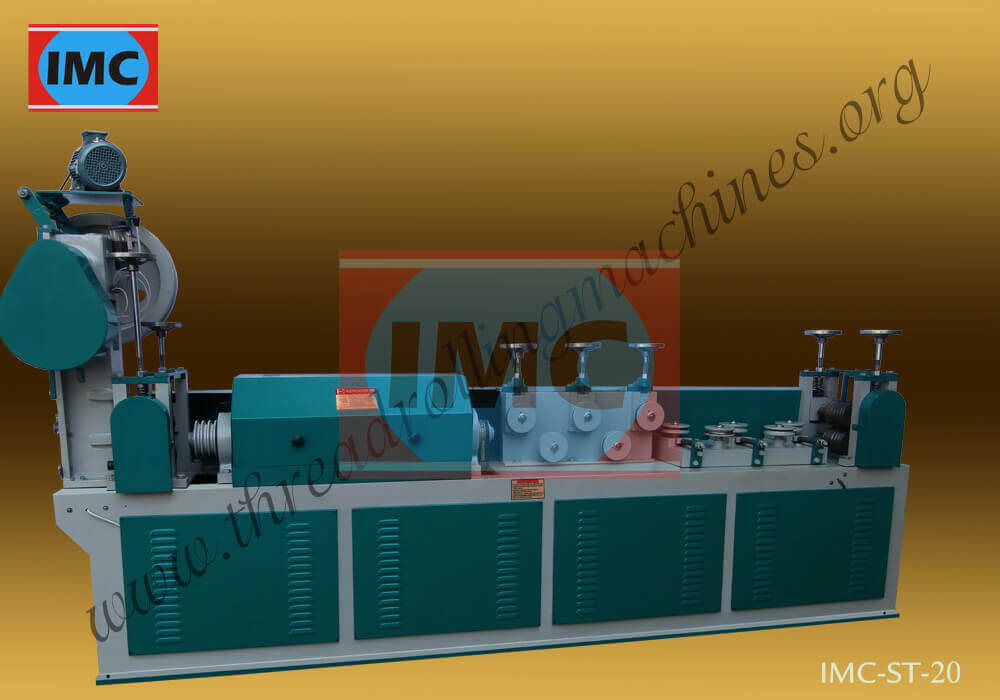

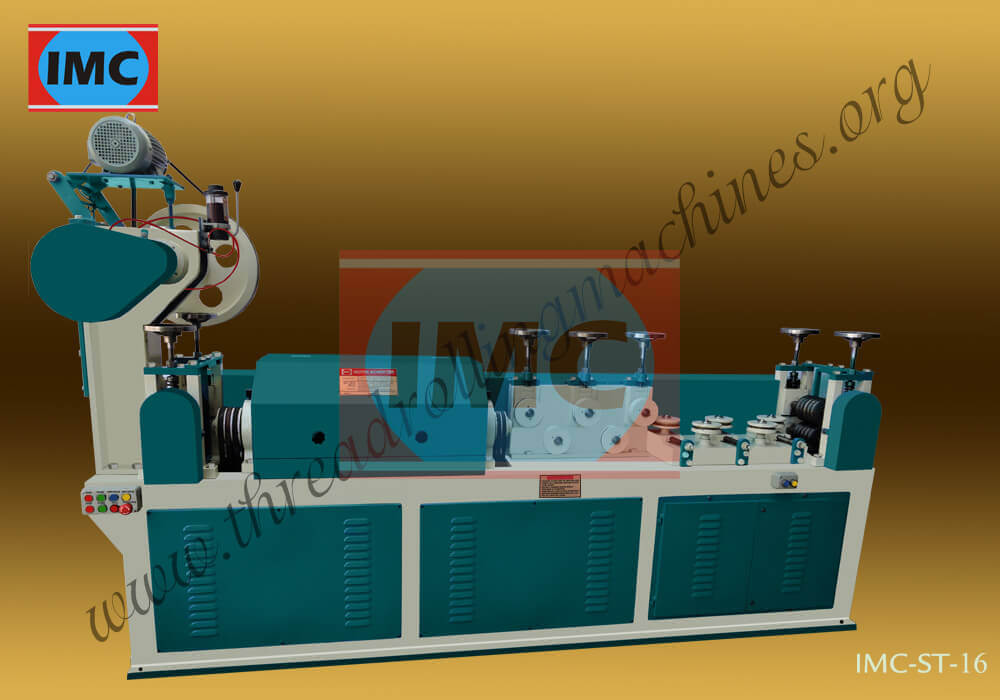

| Specifications : | IMC-ST-14 | IMC-ST-15 | IMC-ST-16 | IMC-ST-20 | IMC-ST-25 |

| In Thickness of wire | 5 to 14mm | 6 to 15mm | 8 to 16mm | 10 to 20mm | 15 to 25mm |

| In Length of wire to be cut automatically | As per Requirement | As per Requirement | As per Requirement | As per Requirement | As per Requirement |

| Feeding capacity per min. | 60" feet | 60" feet | 60" feet | 60" feet | 40" feet |

| Power of motor H.P. | 10 H.P. | 15 H.P. | 15 H.P. | 25 H.P. | 30 H.P. |

| Required R.P.M. | 1440 | 1440 | 1440 | 1440 | 1440 |

| Approx. Weight in Kg. | 1300 | 1500 | 2500 | 3000 | 3500 |

| Floor space required | 91"x22" | 105"x24" | 125"x24" | 150"x27" | 180"x36" |