Pipe Threading Machine

Through our strenuous efforts and stringent hard work that we have done for more than last 7 years, we have gained a reputation and name that is beyond anybody’s imagination. Because of continuously ...

VIEW MORE

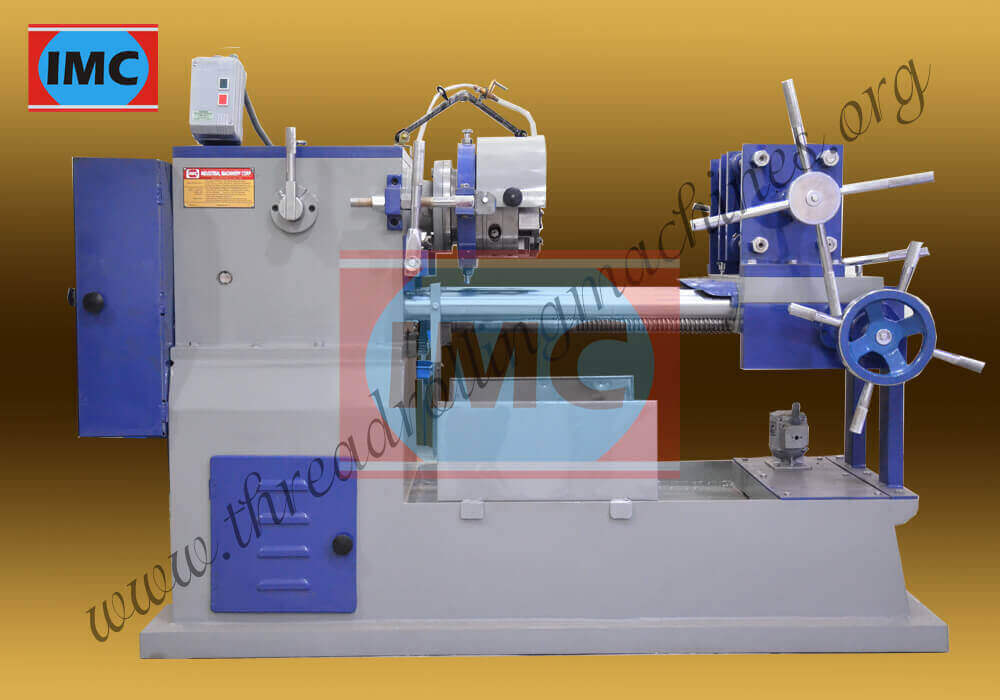

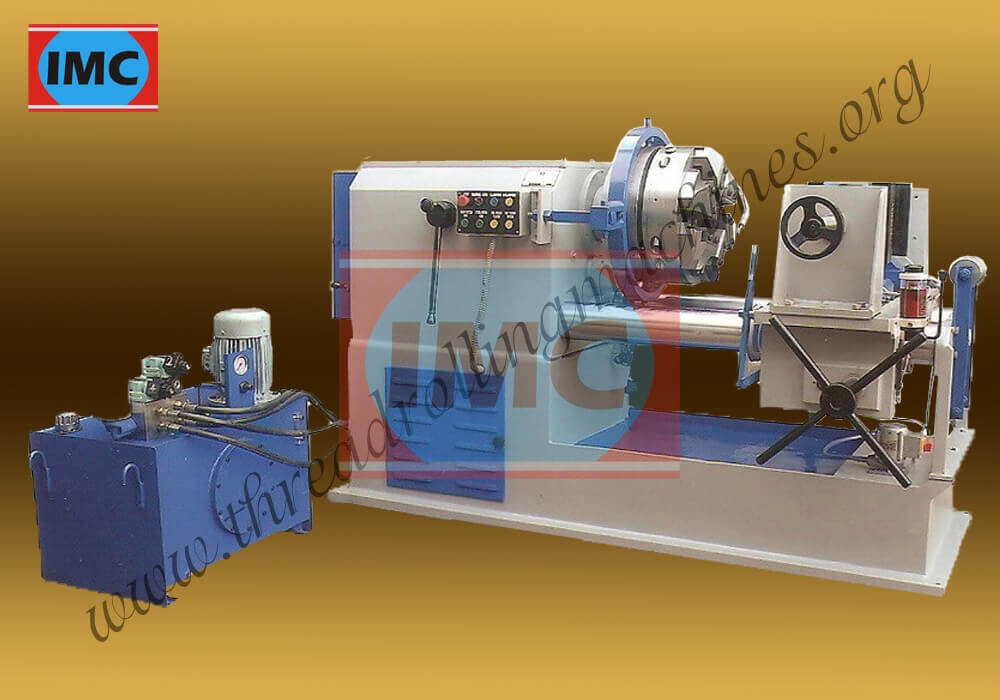

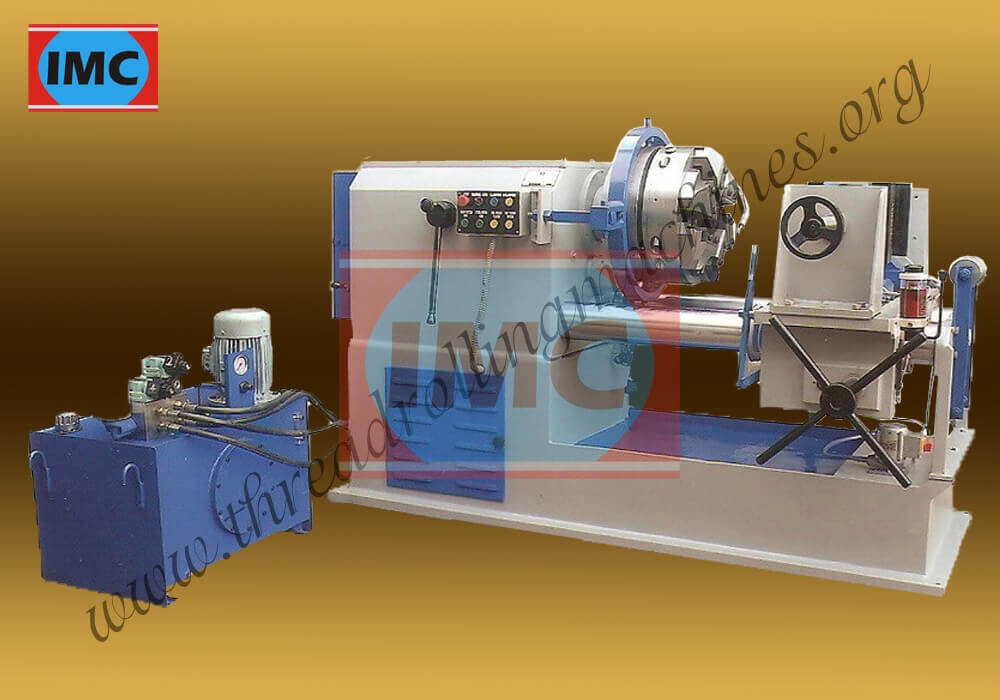

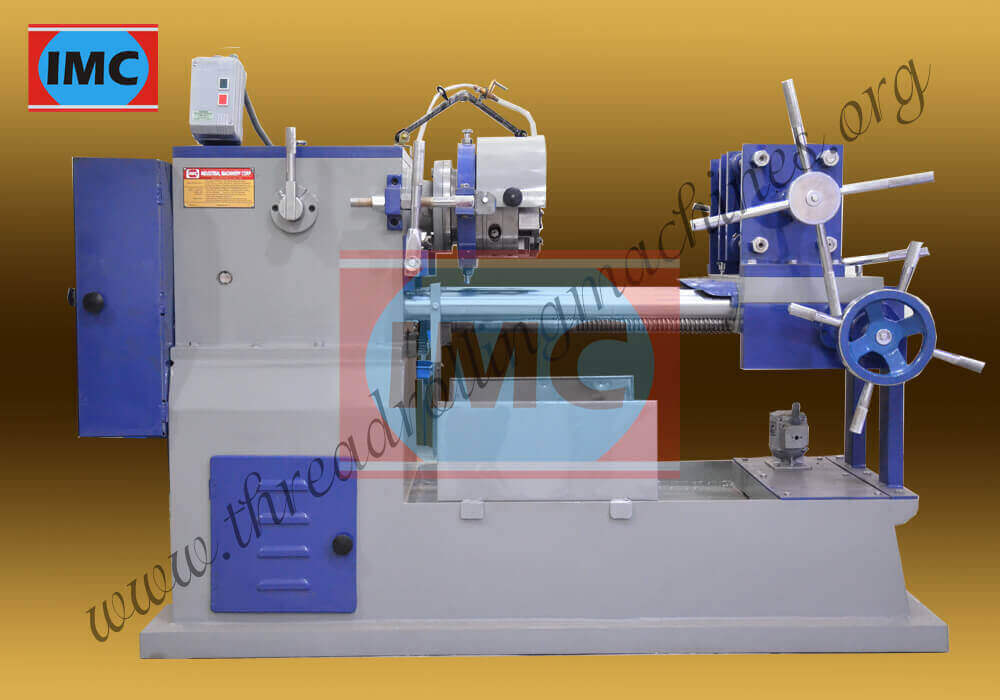

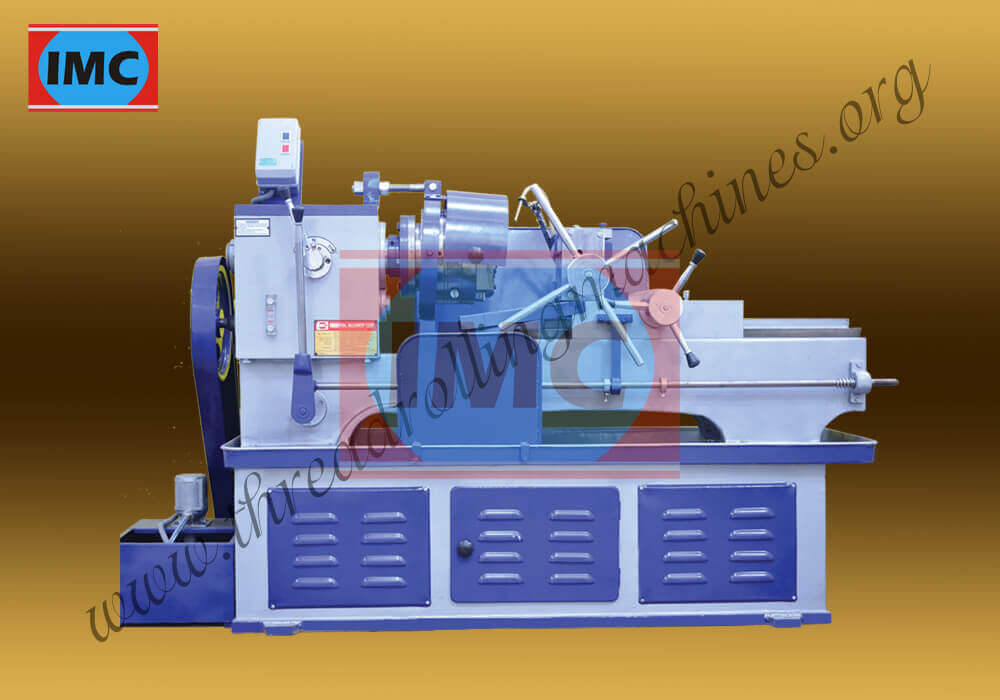

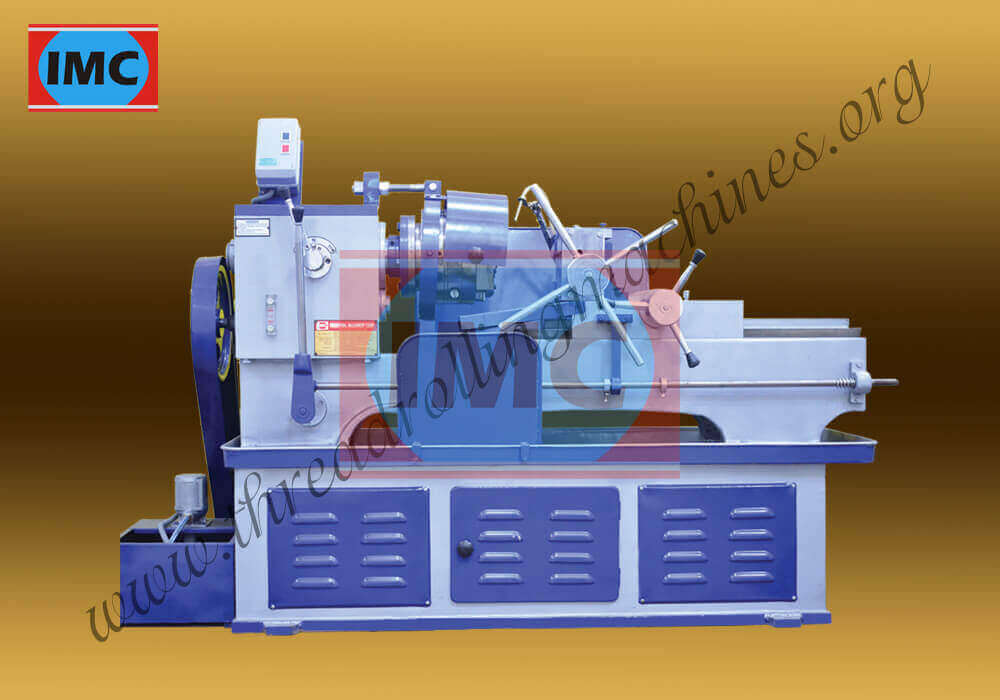

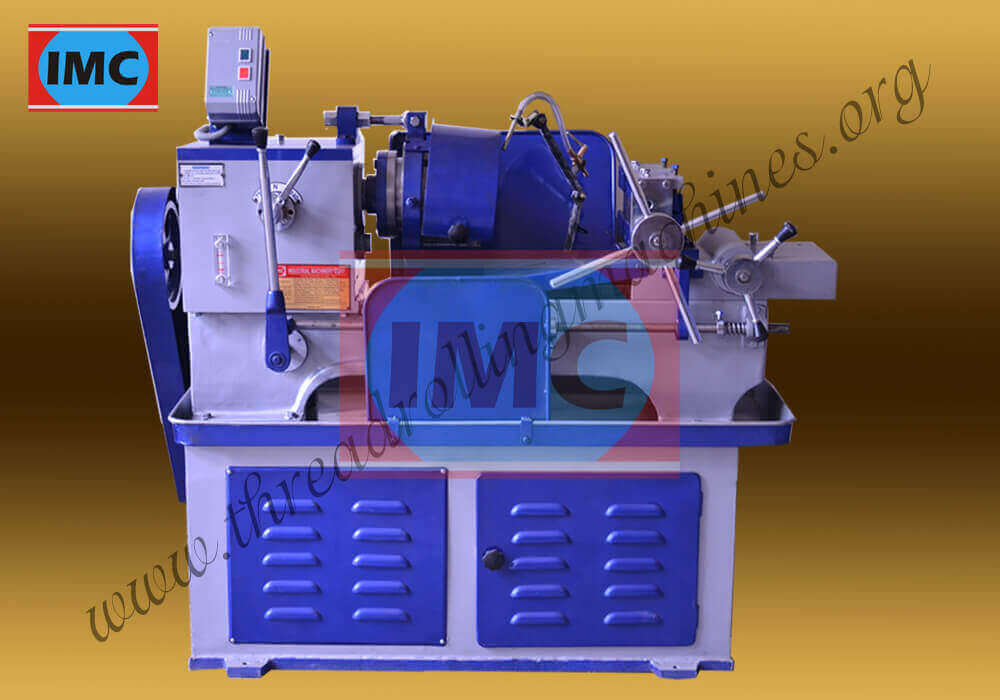

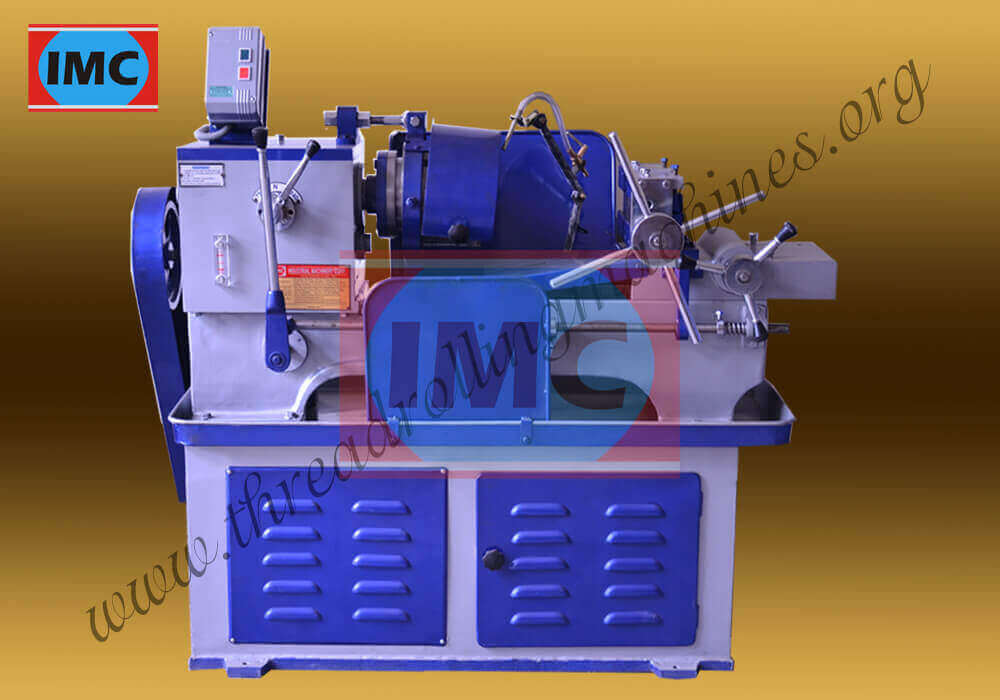

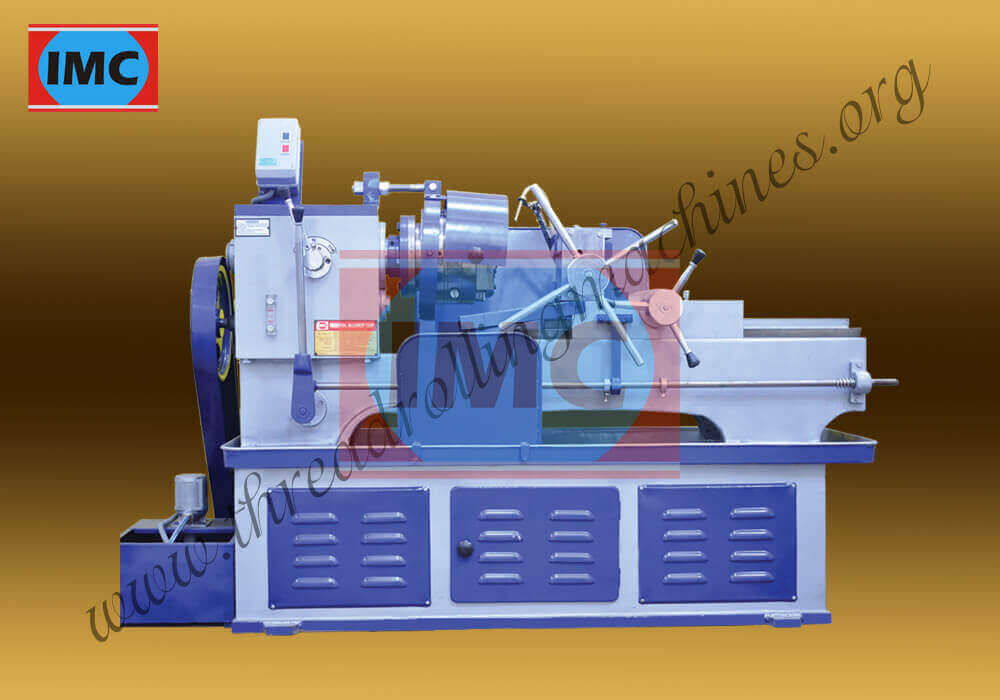

Industrial Machinery Corporation has been in the business of manufacturing industrial machines for more than a decade now and since then only, we have been engaged in manufacturing of quality pipe threading machines. In all these 7 years of being in this business, we have gained enough expertise and skills to built finest quality Hydraulic Pipe Threading Machine. We have designed our Hydraulic Pipe Threading Machine in such a way that since its launch in market, it has been acknowledged as the most perfect and faultless Hydraulic Pipe Threading Machine. Hydraulic Pipe Threading Machine made at our manufacturing unit in Ludhiana is famous in the market for being the most precise and accurate Hydraulic Pipe Threading Machine. It is its design that allows this machine that makes this machine keeps on working for long hours without showing any symptoms of even a slight imperfection in the quality of the results coming out. Popularity of our Hydraulic Pipe Threading Machine is also the result of efficiency, easy and the high-quality performance, this machine provides to its operator while in work. The Hydraulic Pipe Threading Machine that we built is made using only the finest quality raw material and our quality assessment team makes sure that every piece of raw material coming in is without any flaw or fault. If there is any flaw or defect found, that piece is immediately removed. It is due to quality that we maintain of our Hydraulic Pipe Threading Machine, our machines despite looking so sleek and soft, is one of the toughest machines to be every engaged in pipe threading. Our Hydraulic Pipe Threading Machine could be used to draw a big variety of threads on the pipe.

VIEW SPECIFICATIONSThe Hydraulic Pipe Threading Machine that we craft here at our Ludhiana unit has been fitted with a self-opening die head and headstock gears which gives and extra durability and permanence to the machine. This machine has a hydraulic cylinder lead screw box nut engaging, one hydraulic pipe clamping cylinder and one hydraulic cylinder for die-head opening with micro switches with automation with control panel.

With all these power-puffed features, there is not a single possibility that our Hydraulic Pipe Threading Machine will ever show any signs of wear and tear oven of slightest of technical or any other problem. Our quality checks are unsympathetic and hence we rest assure because we know that only the best raw material and best parts would be used to make this Hydraulic Pipe Threading Machine. This machine is made using only the finest of raw materials which makes sure that this machine is ready to work even in the most severe conditions that may arise in the working scenarios.

Let’s have the name of the parts of our Hydraulic Pipe Threading Machine:

| Model | 1/2" to 2.1/2" (Pillar Type) | 1" to 4" (Pillar Type) | 2.1/2" to 6" (Pillar Type) | 4" to 8" (Pillar Type) |

| Saddle Movement | 12" – 16" | 10" – 12" | 8" | 8" |

| Spindle Speed Range | 60-90-120 | 40-75-115 | 25-50 | 25-50 |

| Number of Spindle Speed | 3 | 3 | 2 | 2 |

| Threading Capacity | 1/2" to 2.1/2" | 1" to 4" | 2.1/2" to 6" | 4" to 8" |

| Production per Hour | 70-90 | 35-40 | 20-25 | 15-20 |

| H.P. Power Require (960 RPM) | 7.5 H.P. | 12.5 H.P. | 15 H.P. | 20 H.P. |

| Lead Screw | Automatic | Automatic | Automatic | Automatic |

| Weight (KG) Approx. | 990 | 1600 | 1900 | 2500 |

Hydraulic Pipe Threading Machine Tangential Chaser

IMC Tangential Chasers are manufactured from imported High Speed Steel which must pass exacting metallurgical standard. Experienced heat treatment with the automatic imported heat treatment plant and imported Testing equipment, assures that they will perform satisfactorily in service and produce quality threads within the tolerance for which they ware intended.

IMC Chaser are interchangeable. If one Pc. Of a chaser set is damaged & is beyond use. Then same No. pc. Of the other chaser set lying in stock may be used and there will not be any difference in threading performance and the damaged set can be replaced without the necessity of replacing entire set.

Read More..

Through our strenuous efforts and stringent hard work that we have done for more than last 7 years, we have gained a reputation and name that is beyond anybody’s imagination. Because of continuously ...

VIEW MORE

Being in the business of industrial machinery Corporation manufacturing for more than 12 years, we would advise all the buyers of Bar Threading Machine to have a detailed conversation on what cus ...

VIEW MORE

For more than 12 years, we have been a highly established company in the field of industrial machine manufacturing. And since then we have been successfully manufacturing and supplying the best qualit ...

VIEW MORE

A Rod Threading Machine is a gem of an industrial machine manufactured at our industrial machine manufacturing unit based in Ludhiana. The Rod Threading Machine made by us has been admired by clients ...

VIEW MORE

We have the wide range of semi-automatic Steel TMT Chaser Rebar Threading Machine which is used for the site projects and it does outside threading on TMT bars. Steel TMT Chaser Rebar Threading Machin ...

VIEW MORE

Electric Conduit Pipe Threading Machine is use to thread the external area of the conduit pipes. IMC Machines highly specialized and can be used solely for industry specific purposes. There are only a ...

VIEW MORE

Industrial Machinery Corporation is the manufacturer of Rebar Threading Machine in Ludhiana, Punjab, India TMT Bar Threading Machine / Rebar threading Machine is designed with the features of easy ope ...

VIEW MORE