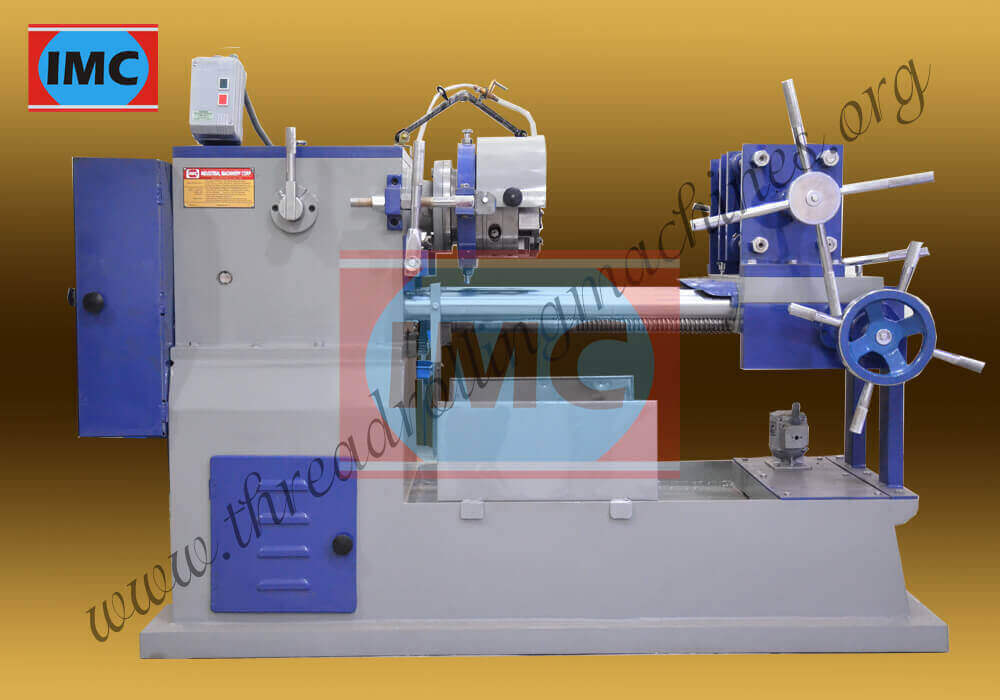

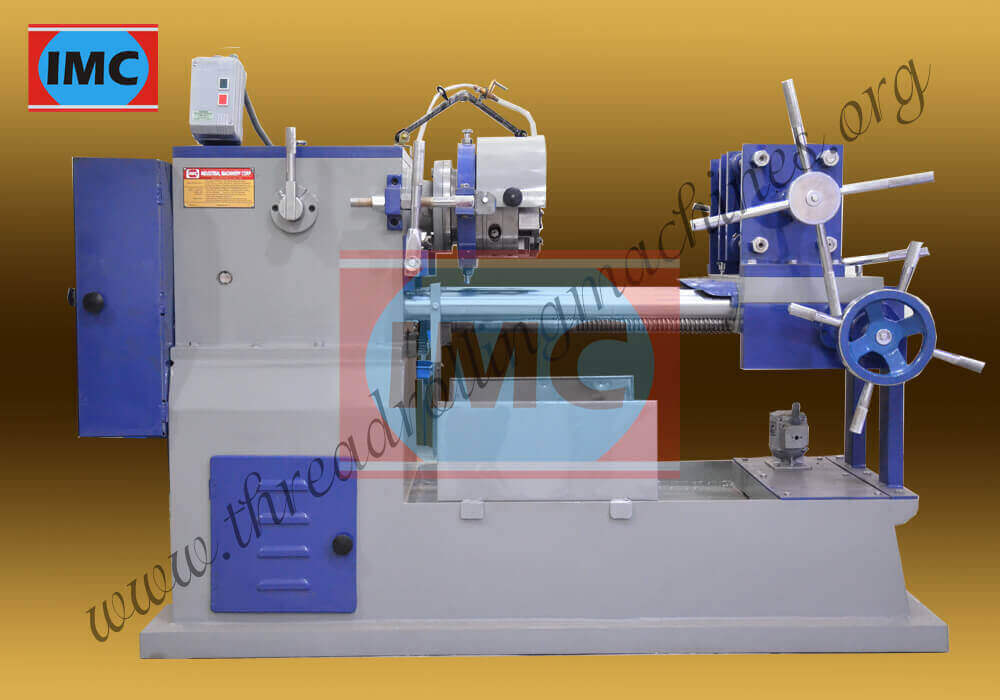

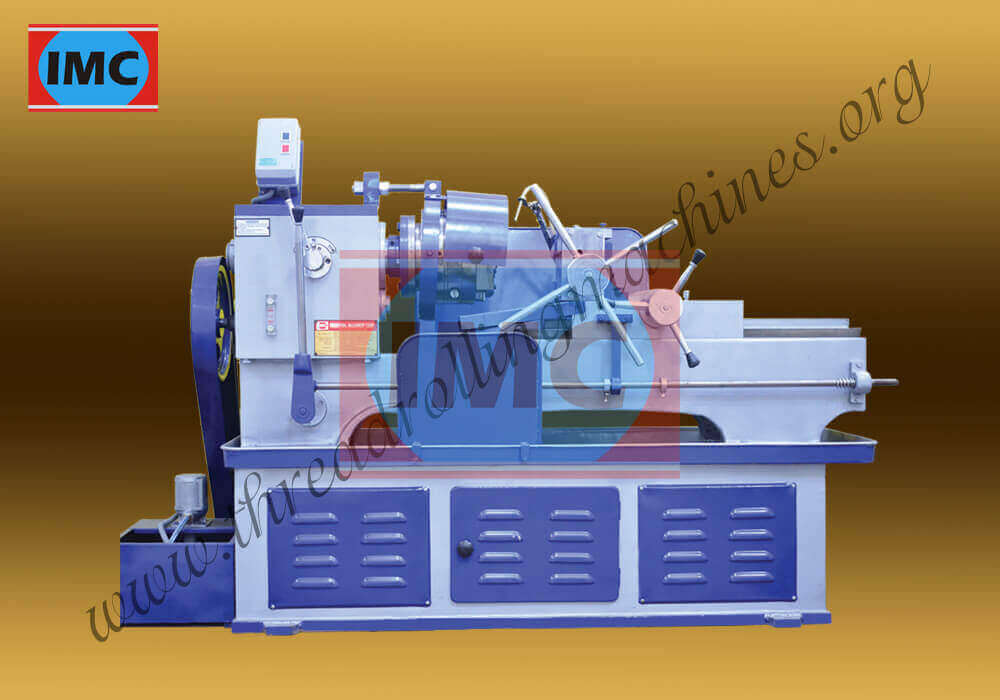

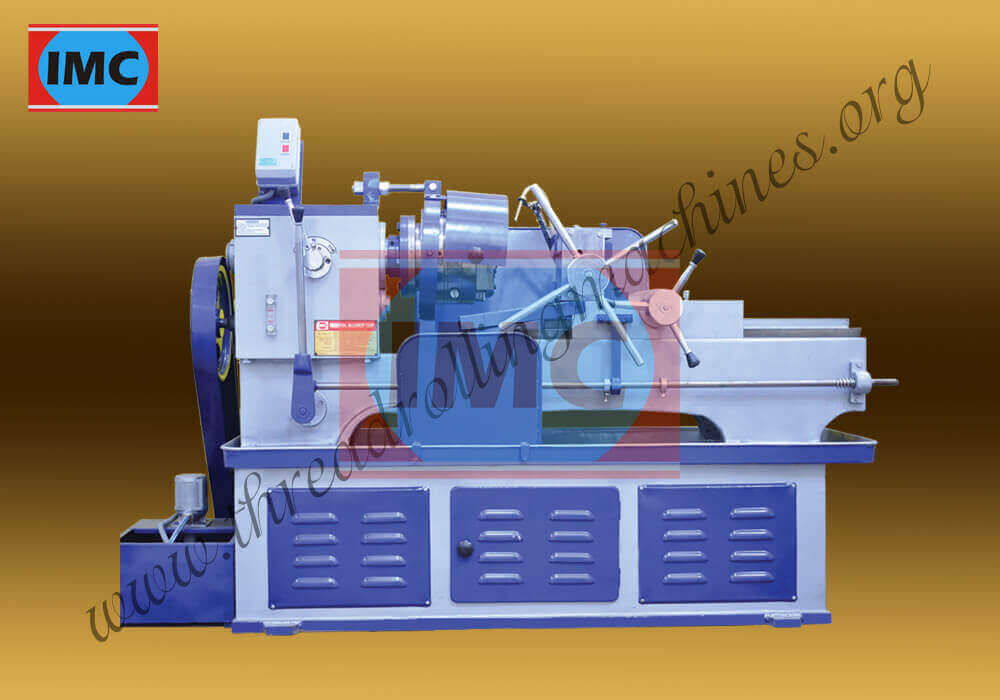

Bar Threading Machine

Being in the business of industrial machinery Corporation manufacturing for more than 12 years, we would advise all the buyers of Bar Threading Machine to have a detailed conversation on what cus ...

VIEW MORE

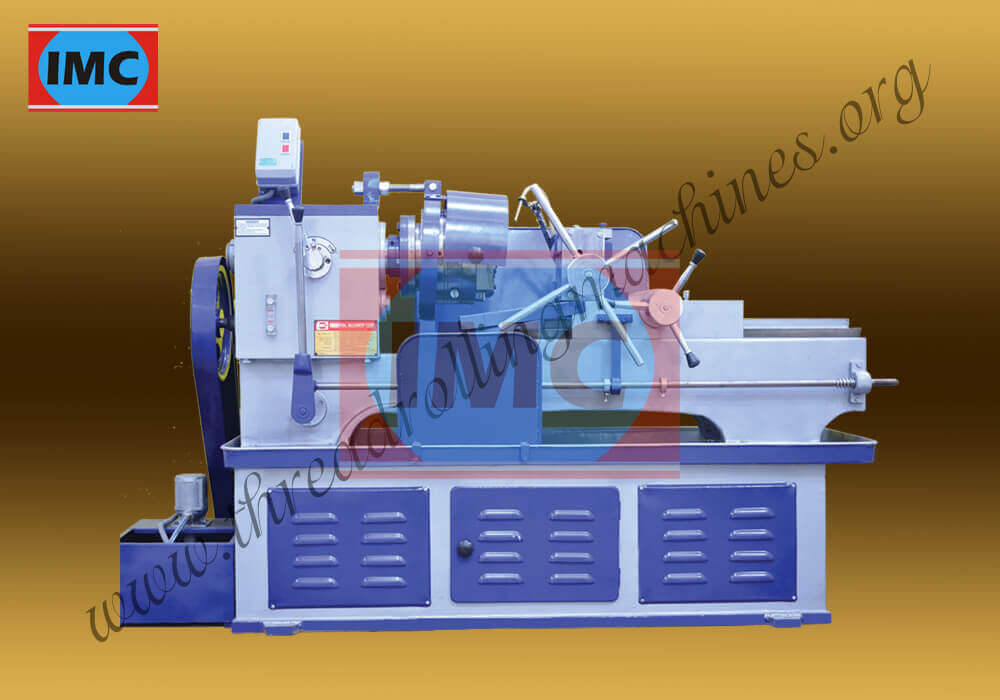

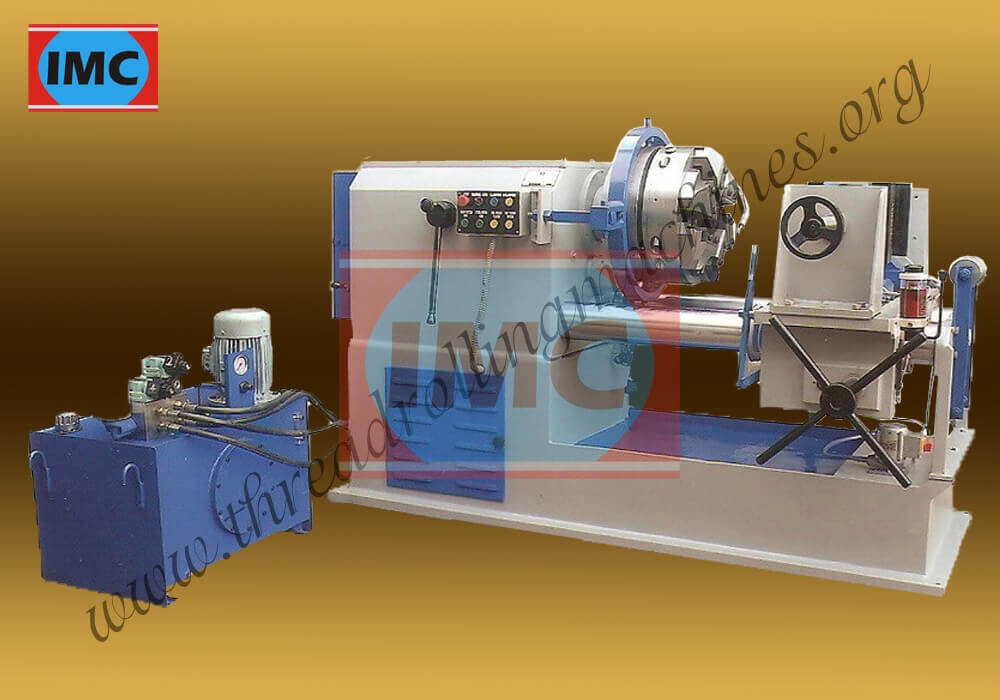

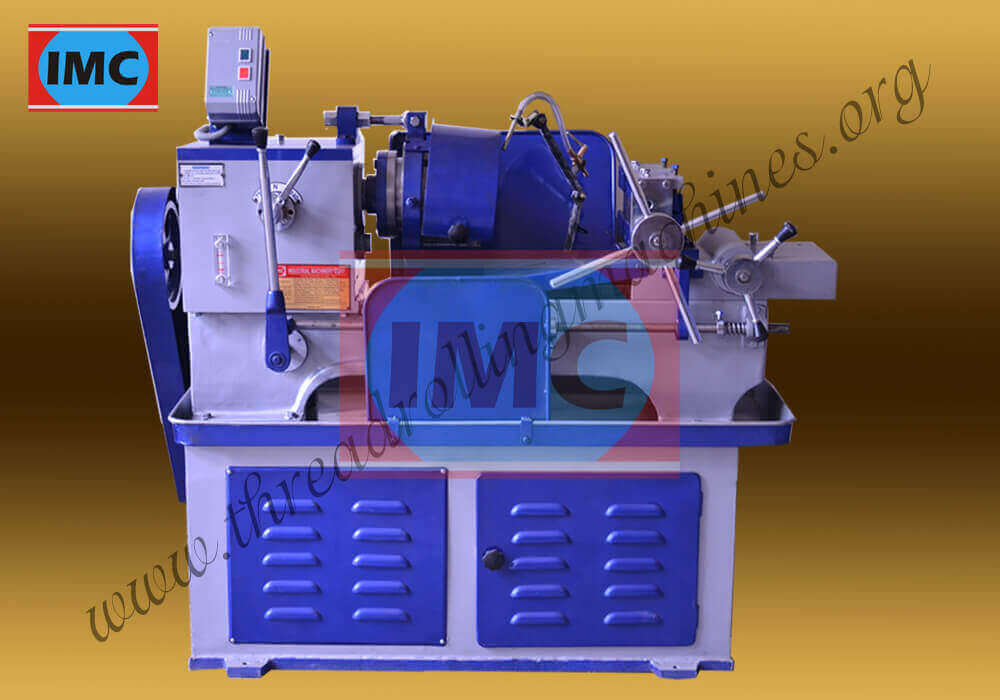

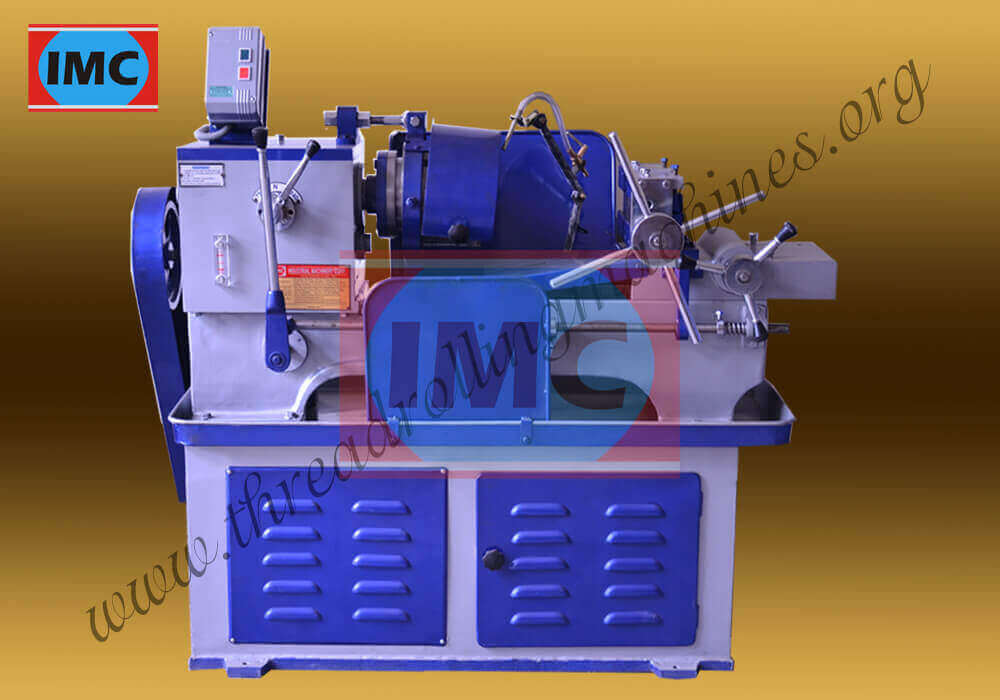

Through our strenuous efforts and stringent hard work that we have done for more than last 7 years, we have gained a reputation and name that is beyond anybody’s imagination. Because of continuously and persistently providing our clients with the best of industrial machines as well as Pipe Threading Machine, we are acknowledged as one of the most influential and prominent players in the market. We have gained much of expertise and using it all, we have mastered the field of manufacturing Pipe Threading Machines. We make our Pipe Threading Machines with utmost care and concern and make sure on every step of production that the quality is not deteriorated at any cost. Over the whole process of manufacturing of our Pipe Threading Machine, we keep our motive very clear before us and that is to satisfy our clients to the fullest of their contentment. This motive of ours has kept us making Pipe Threading Machine better and better every time. Our Pipe Threading Machine has been acknowledged as the best in the business till now and all the credit goes to the technology and skills that we use to manufacture these Pipe Threading Machines.

VIEW SPECIFICATIONS

Apart from keeping the production process under strict vigil, we also never fail to keep the raw material coming in under scrutinized inspection. Prior to use, all the raw material or anything that is going to be used is checked and examined by our quality assessment team. This team makes sure that all the raw material to be used is totally defect-less and flawless. Despite giving so many things in our Pipe Threading Machine we make every effort that we keep the prices well under checks and we do it quite comfortably. This has impressed our clients very much that that we are not in pursuit to make holes in their pockets. Our Pipe Threading Machines are the widest recommended Pipe Threading Machine to the companies who need it by the companies who are already using it. At our manufacturing unit based in Ludhiana, we make three different variants of Pipe Threading Machine and these three variants could be used for multiple purposes in factories and tool-rooms.

The Pipe Threading Machine is designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to form the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speeds. Naturally they are built with high standards of workmanship, material and quantity.

Here is the list of various types of threads that our Pipe Threading Machines can cut:

Mentioned below are the names of various parts of the Pipe Threading Machines that we manufacture at our manufacturing unit based in Ludhiana:

| Model | 3/8" to 2" | 1/2" to 3" | 1" to 4" | 2.½" to 6" | 4" to 8" | 8" to 10" |

| Saddle Movement | 10" - 12" | 16" | 10" – 12" | 8" | 8" | 8" |

| Spindle Speed Range | 127-180 | 60-90-120 | 40-75-115 | 25-50 | 25-50 | 10-20-30 |

| Number of Spindle Speed | 2 | 3 | 3 | 2 | 2 | 3 |

| Threading Capacity | 3/8" to 2" | 1/2" to 3" | 1" to 4" | 2.1/2" to 6" | 4" to 8" | 8" to 10" |

| Production per Hour | 100-120 | 70-90 | 35-40 | 20-25 | 15-20 | 15-20 |

| H.P. Required | 3 H.P. | 7.5 H.P. | 12.5 H.P. 960 | 15 H.P. 960 | 20 H.P. 960 | 30 H.P. 960 |

| Lead Screw | Provided | Provided | Provided | Provided | Provided | Provided |

| Weight (KG) Approx. | 550 | 990 | 1600 | 1900 | 2500 | 5000 |

Pipe Threading Machine Tangential Chaser

IMC Tangential Chasers are manufactured from imported High Speed Steel which must pass exacting metallurgical standard. Experienced heat treatment with the automatic imported heat treatment plant and imported Testing equipment's, assures that they will perform satisfactorily in service and produce quality threads within the tolerance for which they ware intended.

IMC Chaser are interchangeable. If one Pc. Of a chaser set is damaged & is beyond use. Then same No. pc. Of the other chaser set lying in stock may be used and there will not be any difference in threading performance and the damaged set can be replaced without the necessity of replacing entire set.

Read More..

Being in the business of industrial machinery Corporation manufacturing for more than 12 years, we would advise all the buyers of Bar Threading Machine to have a detailed conversation on what cus ...

VIEW MORE

For more than 12 years, we have been a highly established company in the field of industrial machine manufacturing. And since then we have been successfully manufacturing and supplying the best qualit ...

VIEW MORE

Industrial Machinery Corporation has been in the business of manufacturing industrial machines for more than a decade now and since then only, we have been engaged in manufacturing of quality pipe thr ...

VIEW MORE

A Rod Threading Machine is a gem of an industrial machine manufactured at our industrial machine manufacturing unit based in Ludhiana. The Rod Threading Machine made by us has been admired by clients ...

VIEW MORE

We have the wide range of semi-automatic Steel TMT Chaser Rebar Threading Machine which is used for the site projects and it does outside threading on TMT bars. Steel TMT Chaser Rebar Threading Machin ...

VIEW MORE

Electric Conduit Pipe Threading Machine is use to thread the external area of the conduit pipes. IMC Machines highly specialized and can be used solely for industry specific purposes. There are only a ...

VIEW MORE

Industrial Machinery Corporation is the manufacturer of Rebar Threading Machine in Ludhiana, Punjab, India TMT Bar Threading Machine / Rebar threading Machine is designed with the features of easy ope ...

VIEW MORE